CONNECTING WOOD WITH PRECISION

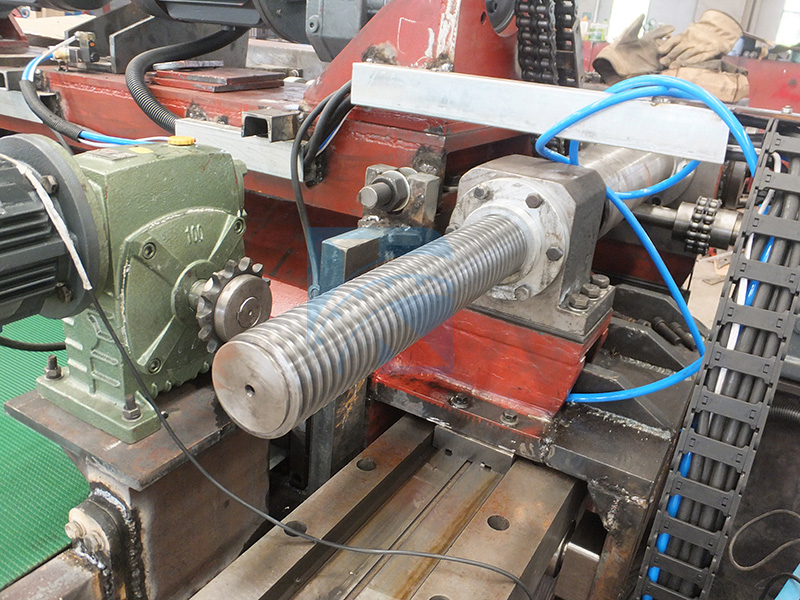

Peeler machine feeding screw

PRODUCT PARAMETERS

- Material: high alloy

- Head hard treatment: YES

- Length: 1575. (customized)

- Diameter:Ø 8mm0, Ø 90mm

- Shaft head: Ø50mm

- Thread distance: 4.39mm (customized)

Description

PRODUCTS INTRODUCTION:

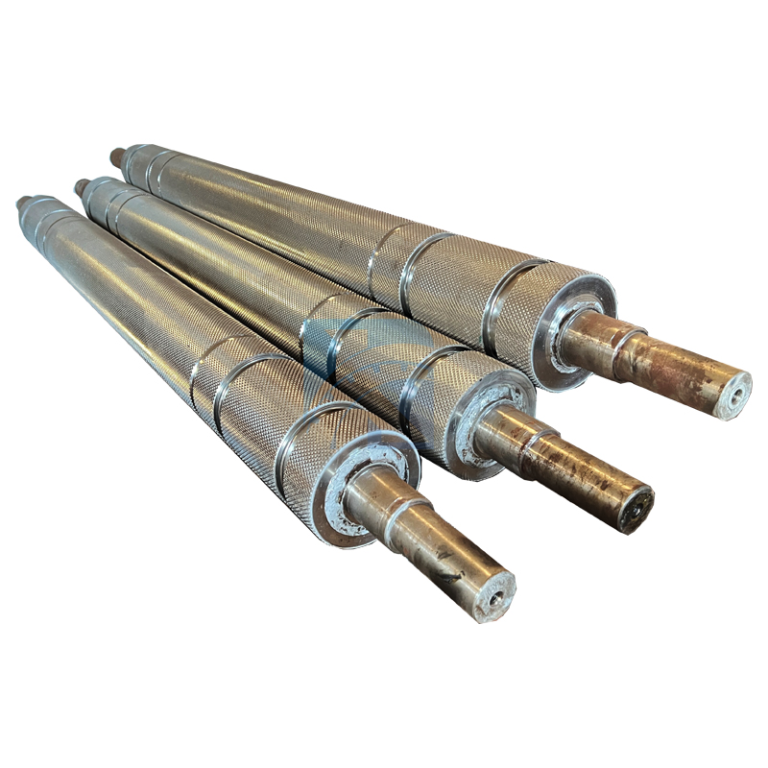

The feeding screw is a very critical component in spindle-less veneer peeling machines, ensuring smooth and precise feeding of logs during the peeling process. These forwarding feed screws are engineered for high performance and durability with quality alloy steel. Confirm screw thread strength and size accuracy.

Our Feeding Screw is specifically designed for spindle-less veneer peeling machines, ensuring efficient and precise wood feeding. This critical component supports smooth operation and enhances peeling accuracy. Both equipment manufacturer and wood products process factory can contact us for this quality peeling machine spare parts supplying.

SPECIFICATION:

Material: high alloy

Head hard treatment: YES

Length: 1575. (customized)

Diameter:Ø 8mm0, Ø 90mm

Shaft head: Ø50mm

Thread distance: 4.39mm (customized)

FEARTURES:

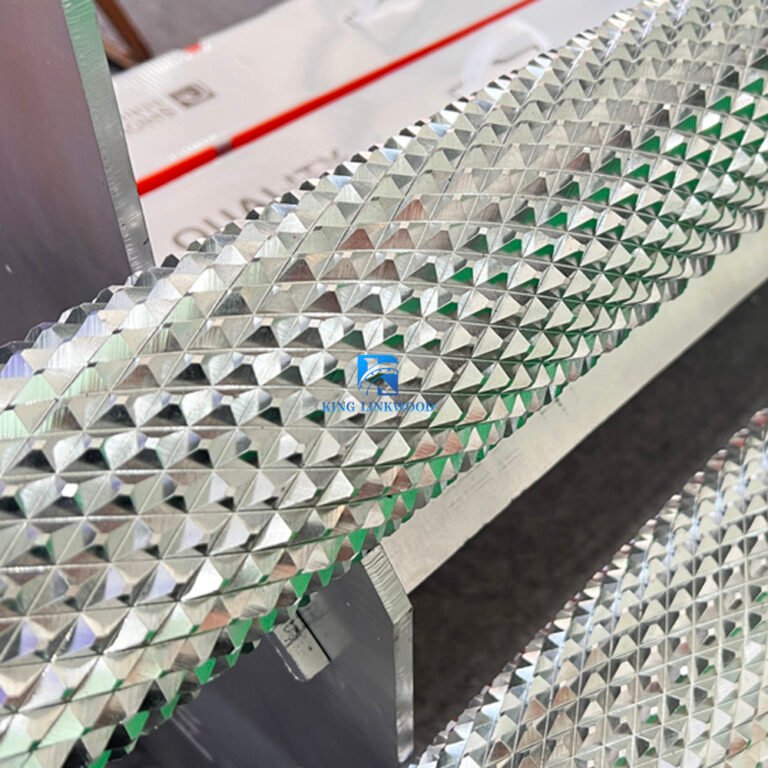

High-Grade Materials: Manufactured from premium high alloy steel, ensuring superior strength and resistance to wear and tear with nut during working.

Precision Engineering: Crafted with advanced CNC machining technology for accurate dimensions and a perfect fits to the nut and matching peeler electrical system.

Hardened Surface: Treated with heat and surface hardening processes to enhance durability and extend service life in high temperature and high strength working.

Customization Designs: Available in various sizes and thread patterns to suit different peeling machine models and requirements. (length,diameter, thread size.etc support customizing)

Applications:

- Suitable for both hardwood and softwood logspeeling machine with different speed needs.

- Compatible with 4ft, 8ft, and 10ft spindle-less veneer peeling machines.

- Designed for consistent performance in high-demand veneer production environments.

Advantages:

- Enhances feeding precision and operational stability.

- Improves veneer quality by ensuring uniform log movement.

- Reduces downtime with long-lasting performance and low maintenance needs.

For any customization or inquiries about our feeding screws, feel free to contact us. We provide tailored solutions to meet the unique demands of your veneer peeling equipment operations.

USAGE SCENARIO:

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888