CONNECTING WOOD WITH PRECISION

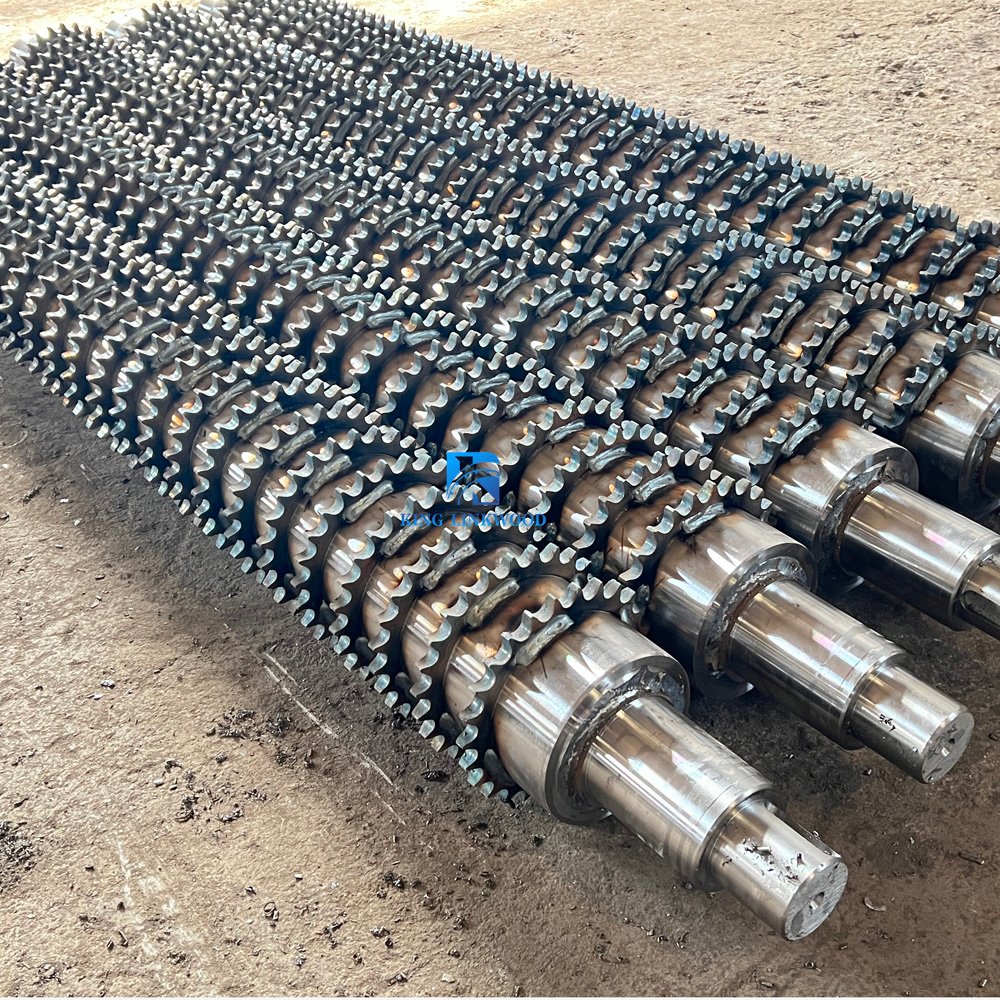

Heavy-Duty Gear Type Log Debarker Roller for Log Rounding Machines

PRODUCT PARAMETERS

- Material:45# steel (Quenched & Tempered)

- Working Width:4 ft / 6 ft / 8 ft/10ft (customizable)

- Roller Diameter:Ø120 – Ø200 mm

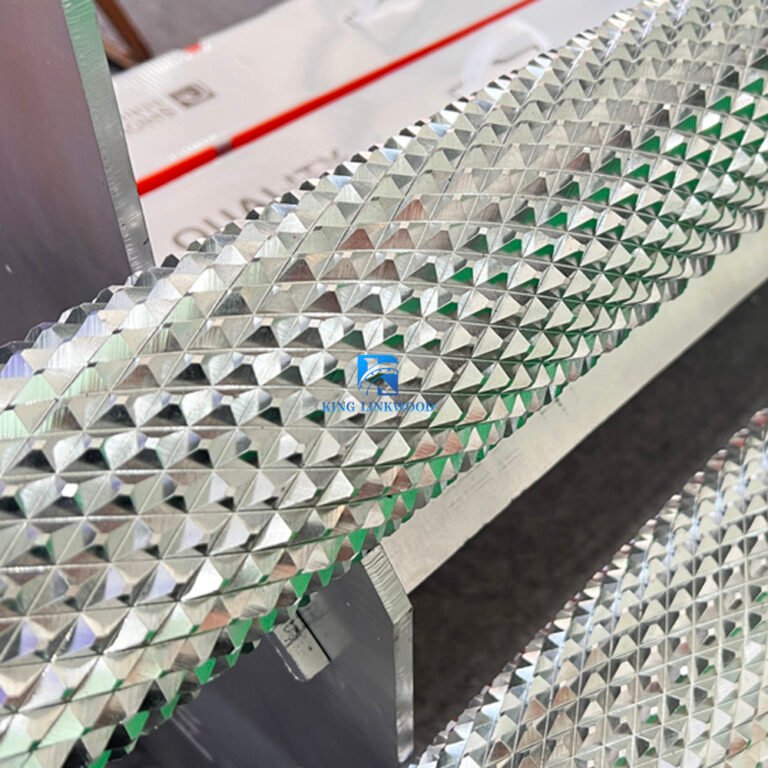

- Surface Pattern:gear type, saw tooth type, big teeth type .etc (customize)

Description

Products Introduction:

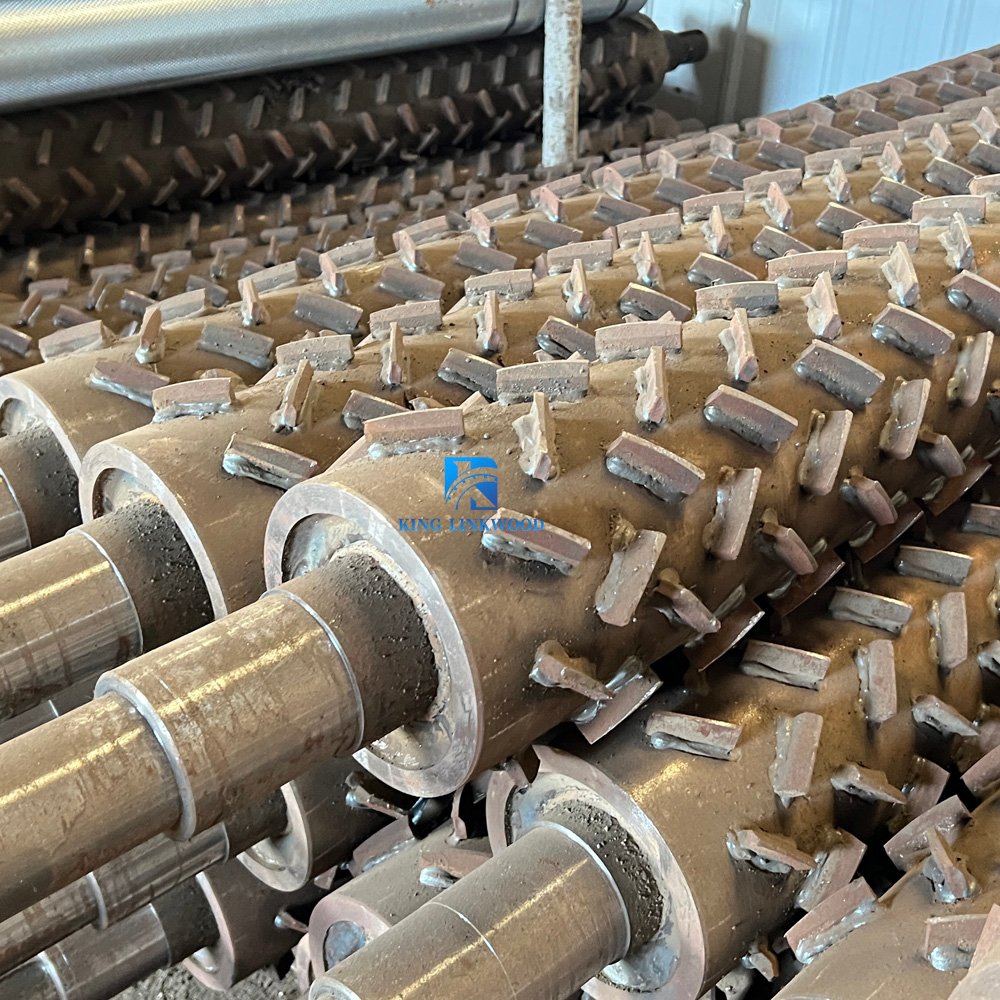

Designed for log debarking and rounding machines, this gear / serrated roller removes bark and corrects log shape before peeling or sawing.

Made from welded 45# steel, it focuses on impact resistance, torque transmission, and durability rather than fine precision.

Core Advantages:

Strong mechanical bite for hardwood and softwood.

Simple structure, low maintenance cost.

Custom tooth profile and roller size available.

Suitable for heavy-duty preprocessing lines.

Applications

Log debarking machines, log rounding machines, veneer production preprocessing lines.

Send us your machine brand, model, and roller drawing for a fast quotation.We support OEM customization, global shipping, and a after sale services.

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888