CONNECTING WOOD WITH PRECISION

Multi-Inlet & Outlet Oil Circuit Design Elevates Short Cycle Laminating Press Performance

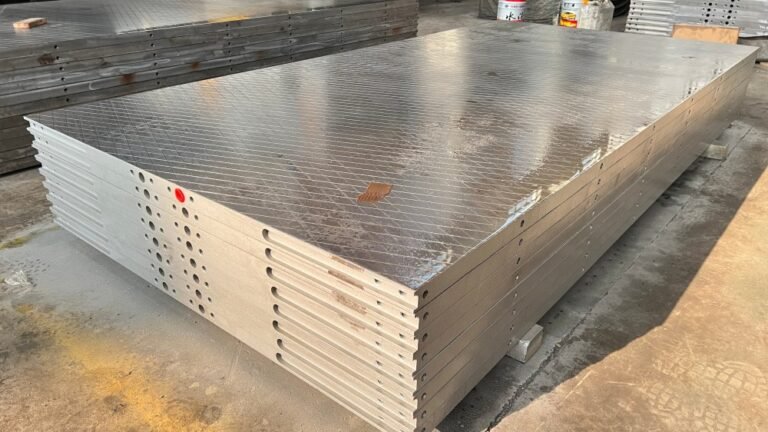

In the competitive wood-based panel manufacturing sector, thermal uniformity and production efficiency are critical to delivering high-quality laminated products. A breakthrough in hot press plate oil circuit design—featuring multi-inlet and outlet configurations—has emerged as a game-changer for short cycle laminating presses (1000T-3200T), addressing long-standing challenges of uneven heating and template deformation. This innovation, tailored for large-format panel production (up to 2150×2750mm), is setting new standards for precision and reliability in furniture board, flooring, and cabinet panel manufacturing.

The Evolution of Oil Circuit Design: From Single to Multi-Channel Systems

Traditional short cycle laminating presses relied on single-inlet and single-outlet oil circuits, which often resulted in temperature drops along the oil flow path. This inconsistency led to uneven heating across the hot press plate, causing steel template warpage and compromising the adhesion quality of decorative films or veneers . To overcome these issues, industry leaders have adopted multi-inlet and outlet configurations—2-in-2-out, 4-in-4-out, and 6-in-6-out—designed to optimize thermal oil circulation.

“The core goal of this design upgrade is to eliminate temperature gradients within the hot press plate,” explains a senior engineer at a leading press manufacturer. “By implementing symmetrically arranged multi-channel circuits, thermal oil flows evenly through the plate’s internal channels, ensuring a maximum temperature difference of ≤5℃ across the entire working surface—an essential requirement for short cycle laminating processes.”

Key Advantages of Multi-Inlet & Outlet Oil Circuits

- Superior Thermal Uniformity: The parallel and zigzag-shaped internal channels (with 25-30mm diameters ) paired with multi-inlet/outlet setups enable balanced oil flow, eliminating “dead zones” where heat accumulates or dissipates unevenly. This directly addresses the deformation issues caused by asymmetric heating .

- Enhanced Production Efficiency: Thermal oil, which operates at 200℃ (up to 340℃ for high-performance variants ), circulates faster through multi-channel systems, reducing heat-up time and enabling shorter press cycles. For 2400T-3200T presses handling large-format panels (2150×2750mm), this translates to a 15-20% increase in throughput.

- Extended Equipment Lifespan: Uniform heat distribution reduces mechanical stress on the hot press plate and hydraulic system. When combined with high-quality structural steel (Q355/45 steel ) and precision CNC machining, the multi-channel design extends the hot press plate’s service life to 8-10 years.

- Flexible Compatibility: The configurations are customized to match press tonnages and plate sizes. Smaller presses (1000T-2000T) use 2-in-2-out systems, while mid-range (2000T-2400T) and heavy-duty (2400T-3200T) models adopt 4-in-4-out and 6-in-6-out designs, respectively—ensuring optimal performance across all applications.

Industry Adoption and Future Trends

Major manufacturers of short cycle laminating presses have already integrated this multi-inlet/outlet oil circuit design into their product lines, particularly for upper-mounted cylinder models. The technology aligns with the industry’s shift toward energy-efficient and high-precision equipment, as thermal oil circulation systems eliminate the need for expensive boiler infrastructure (unlike steam heating ) while offering both heating and cooling capabilities via heat exchangers .

Looking ahead, advancements in oil circuit design will focus on smart temperature monitoring and flow rate optimization, further enhancing process control. As demand for large-format and high-quality laminated panels grows, the multi-inlet & outlet oil circuit is poised to become a standard feature in next-generation short cycle laminating presses.

For manufacturers seeking to upgrade their production lines, this innovation represents a strategic investment in quality, efficiency, and long-term operational reliability—solidifying its position as a defining development in the woodworking machinery sector.