CONNECTING WOOD WITH PRECISION

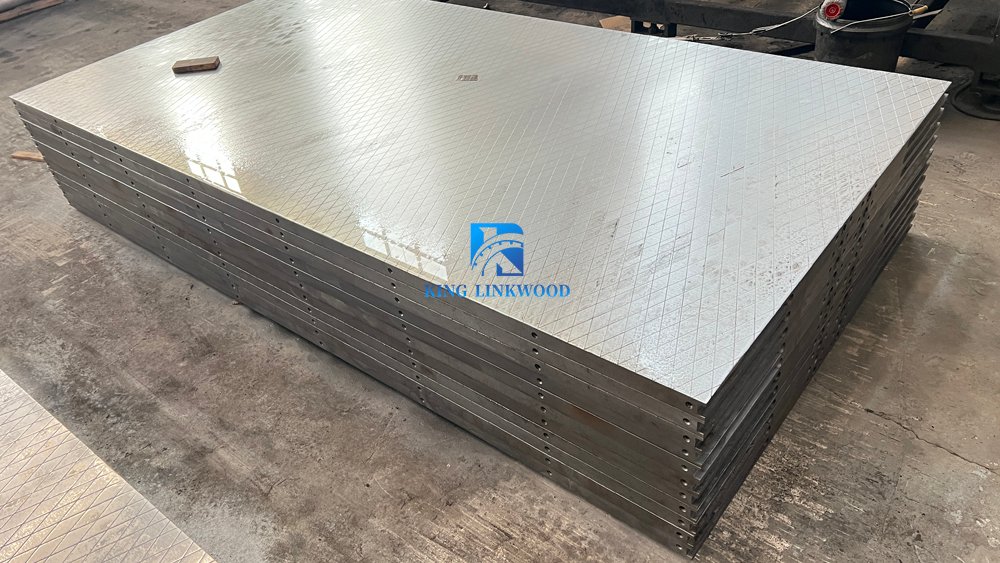

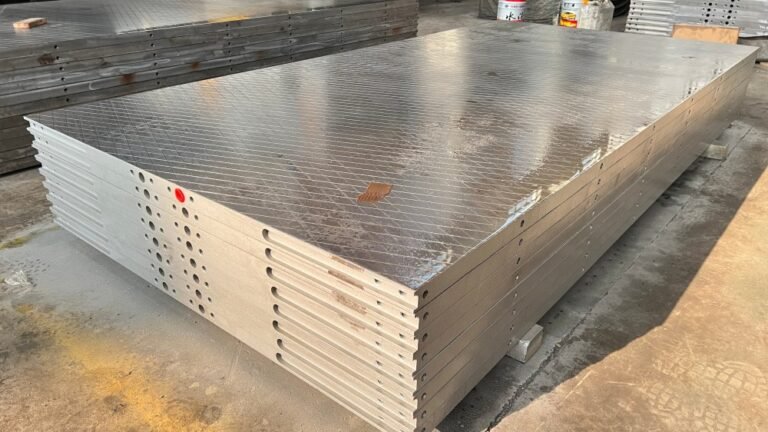

Hot Platen: Core Component for High-Efficiency Heat Transfer in Press Machinery.

Help you choose suitable hot plates spare parts.

Firstly, A introduction to the hot press plates.

The hot platen is a critical core component for various hot press machines, playing a important role in ensuring stable and efficient heat transfer during the pressing process.

Its primary working principle involves the circulation of a heat carrier (such as thermal oil, water, or steam) within the platen’s internal channels. As the heat carrier flows through, the platen rapidly reaches and maintains a consistent high temperature. This generated heat is then uniformly transferred to the adhesive on the target board, enabling the paper or veneer to be firmly bonded to the board surface—ultimately guaranteeing the quality and durability of the finished product.

Core Material & Standard Specifications

High-Quality Base Material:

The platen is manufactured using Q235B steel as the standard material.

If for scenarios requiring higher mechanical strength and load-bearing capacity (e.g., heavy-duty plywood production,accurate film face lamination pressing, MDF board production.etc), Q345 steel is available as an upgraded option, ensuring long-term resistance to deformation under high temperature and pressure.

Flexible Different Size Options:

Standard sizes include 4×8, 6×8, and 6×12 (units can be customized based on regional market habits and products making needs, such as inches or centimeters). Beyond standard specifications, fully customized size solutions are offered to match the unique dimensions of different hot press machines. Common customized width×length combinations include 1100×2100mm, 1370×2700mm, 1500×2600mm, and 1400×2600mm, with thickness options ranging from 42mm to 140mm (e.g., 42mm, 52mm, 60mm, 80mm, 100mm, 120mm, 140mm). Thickness tolerance is strictly controlled within ±1mm to meet precise installation and heat transfer requirements.

Higher Standard Technical Parameters (Guaranteeing Precision & Performance)

To address the demands of high-end woodworking and panel production, the hot platen adheres to strict higher-standard technical indicators:

Heat Carrier Compatibility: Versatile design supports three common heat carriers—oil, water, and steam—adapting to different production process requirements and energy supply conditions.

Surface Parallelism: The surface parallelism tolerance is maintained at 0.05mm per square meter, ensuring even pressure distribution across the entire platen surface during pressing, thus avoiding uneven bonding or board warping.

Surface Smoothness: Surface smoothness accuracy is less than 1.8 microns, minimizing friction between the platen and the board/veneer, and preventing scratches on the finished product surface.

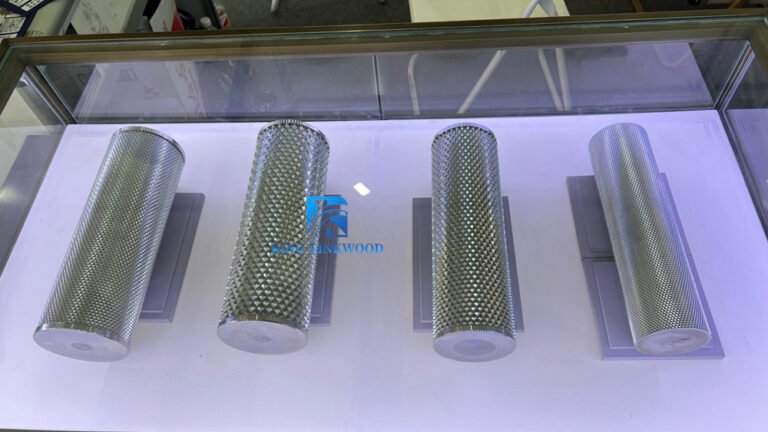

Internal Channel Specifications: Internal cross holes (for heat carrier circulation) have a default diameter of 30mm or 25mm, with a fixed distance of 90mm between adjacent cross channels. This optimized channel layout ensures uniform heat distribution. Additionally, the alignment accuracy of internal channels is controlled within 0.033mm, preventing heat carrier flow blockages and ensuring stable heat transfer efficiency.

Welding Quality: The hydraulic pressure resistance of welding gaps reaches 30kg/cm², effectively preventing heat carrier leakage and ensuring safe operation under high temperature and pressure.

Temperature Uniformity: The surface temperature uniformity tolerance is within 3°C, a key parameter that guarantees consistent adhesive curing across the entire board surface, directly improving the qualification rate of finished products.

Customization Support

We fully support customer-specific customization needs. Whether it is non-standard size requirements, special heat carrier adaptation, or unique thickness specifications, we can develop and produce products that meet your exact demands.

If you have old machine or special shaped machine need change the hot platens, just need provide us the size, and when it comes to the design drawings or technical parameters, we can help you to design,our engineering team will collaborate closely with you to ensure the final product perfectly matches your production equipment and process requirements.