CONNECTING WOOD WITH PRECISION

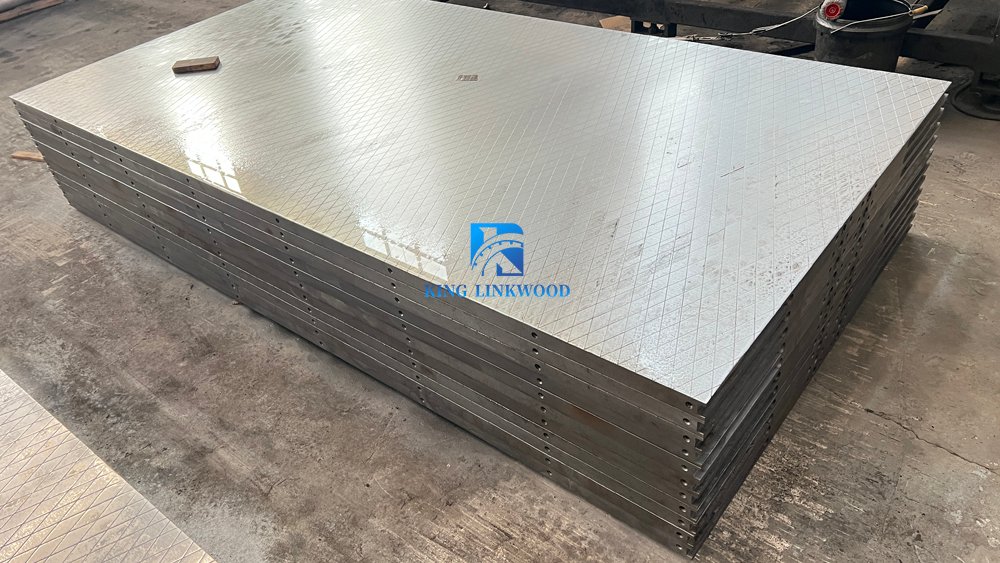

Diamond-Grooved Hot Press Platen / Cross-Hatched Hot Press Plate

Boost Your Veneer Drying & Plywood Pressing Efficiency with Precision-Engineered Diamond-Grooved Platens

If you’re in the woodworking or panel manufacturing industry, you know that moisture control and thermal efficiency are the keys to producing high-quality veneers and plywood. Our Hot Press Platen with Cross-Hatched Grooves (also known as Diamond-Grooved Hot Press Plate) is designed to solve your most pressing production challenges, delivering faster drying times, consistent heat transfer, and long-lasting durability.

Key Benefits That Drive Your Production Forward

1. Diamond-Grooved Surface for Excellent Moisture Evacuation

The precision-machined cross-hatched (diamond) groove pattern creates a network of channels that actively pulls moisture from wood veneers during the hot pressing process. This design:

- Reduces drying time by up to 25% compared to smooth platens

- Minimizes veneer warping, bubbling, and defects

- Ensures uniform moisture distribution for higher-quality end products

- Works seamlessly with both softwood and hardwood veneers

2. Use standard Q235 & Q345 Steel for Long-Term Reliability

Our platens are manufactured from Q235 and Q345 structural steel, chosen for their:

- Excellent thermal conductivity for consistent heat transfer

- High resistance to deformation under high-temperature, high-pressure conditions

- Durability to withstand continuous, heavy-duty production cycles

- Low maintenance requirements and extended service life

3. Fully Designing and Customization Support to Fit Your Exact Needs

We understand that many old model type machines still under service and some may hard to find suitable replacement parts like the hot platens. That’s why we offer complete customization:

- Custom Dimensions: Thickness (35mm–100mm), length, and width accordingto your existing hot press equipment

- Groove Pattern Options: Adjust groove density, depth, and angle for specific veneer drying or plywood bonding requirements

- Surface Finishing: Optional polishing, anti-corrosion coating, or heat treatment for enhanced performance

- Material Upgrades: High-strength steel grades available for extreme operating conditions

Ideal Applications

Our Diamond-Grooved Hot Press Plate is the perfect solution for:

Veneer Dryers: Accelerate moisture removal from natural wood veneers for faster, more efficient drying

Plywood Hot Presses: Ensure strong, uniform bonding by optimizing heat transfer and moisture evacuation

Engineered Wood Panel Production: Deliver consistent results for laminated boards, MDF, an particleboard

High-Volume Woodworking Facilities: Reduce downtime and improve overall production throughput

Technical Specifications

| Parameter | Details |

| Material Grade | Q235, Q345 (custom high-strength steel available on request) |

| Groove Pattern | Standard diamond/cross-hatched (fully customization) |

| Thickness Range | 35mm–100mm (custom sizes available) |

| Surface Tolerance | ±0.1mm for groove depth and spacing |

| Temperature Resistance | Up to 250°C (continuous operation) |

| Surface Finish | Machined, polished, or anti-corrosion coated (optional) |

Why Choose Our Hot Press Platens?

When you invest in a Diamond-Grooved Hot Press Plate from us, you’re not just buying a component—you’re upgrading your entire production process. Our platens are precision-engineered to deliver:

- Faster drying cycles and higher throughput

- Reduced waste from veneer defects

- Lower energy costs through improved thermal efficiency

- A reliable, long-lasting solution that minimizes maintenance

Get Your Custom Quote Today

Get Your Custom Quote Today

Ready to optimize your veneer dryer or plywood hot press? Contact our engineering team to discuss your specific requirements and receive a full set solution and suggestions for your woodworking production. Whether you need a standard Q235 hot press platen for veneer dryer or a fully customized diamond-grooved hot press plate for plywood, we have the expertise to deliver.