CONNECTING WOOD WITH PRECISION

Customized Diamond Rollers for Spreader Machines: Why Standard Rollers Are Not Always Enough

Each particleboard or MDF board production line operates under different conditions.Standard diamond rollers may not meet specific requirements related to pattern design, size, or application layer.

Meanwhile the Customized Diamond Rollers can help to optimize production stability and board quality.

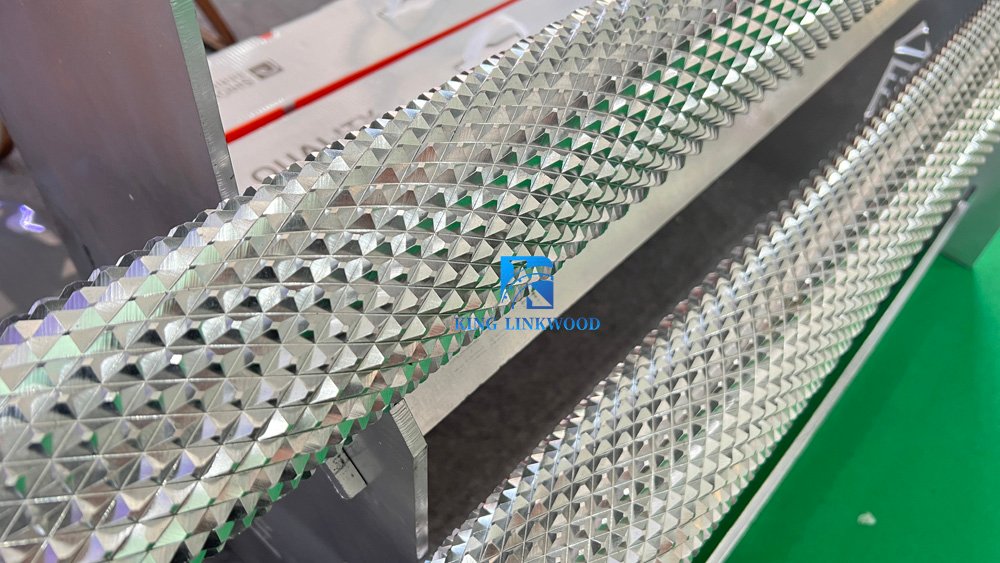

Pattern Customization

Available surface designs include:

* Diamond patterns

* Mesh patterns

* Left-hand & right-hand helical grooves

Surface roughness and tooth density can be adjusted:

* Fine teeth for face layers

* Medium or coarse teeth for core layers

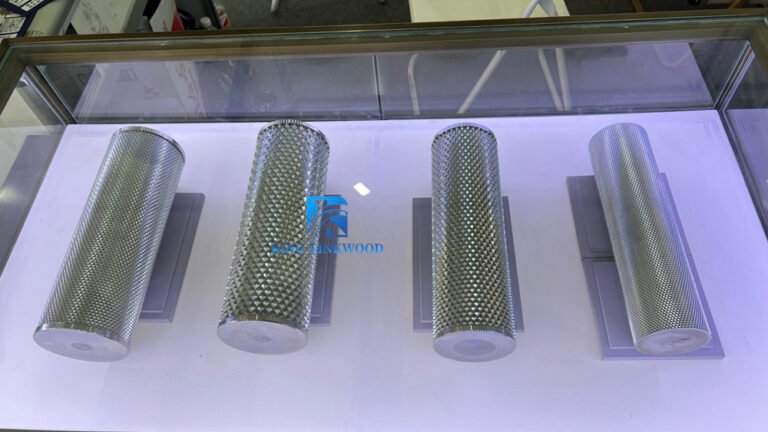

Size Flexibility

* Standard widths: 4 ft / 6 ft / 8 ft

* Diameter range: Ø70–120 mm

* Non-standard sizes available upon request

Precision Control

CNC spiral milling and grinding ensure:

* Uniform pattern depth

* Runout tolerance ≤ **0.05 mm/m**

* Stable high-speed operation

Quality Assurance

All customized rollers undergo:

* Raw material inspection (40Cr steel)

* Heat treatment control

* Dynamic balance testing

Customized diamond rollers improve material distribution efficiency and extend service life.

We provide ‘engineering-based design support’ and a ‘ within normall use enjoy1-year warranty’for customized rollers.