CONNECTING WOOD WITH PRECISION

CASE

South American Client peeler electrical parts

A client in a South American country faced difficulties sourcing compatible inverter parts for their rotary veneer peeling machine after several years of operation. The local suppliers offered expensive alternatives that didn’t…

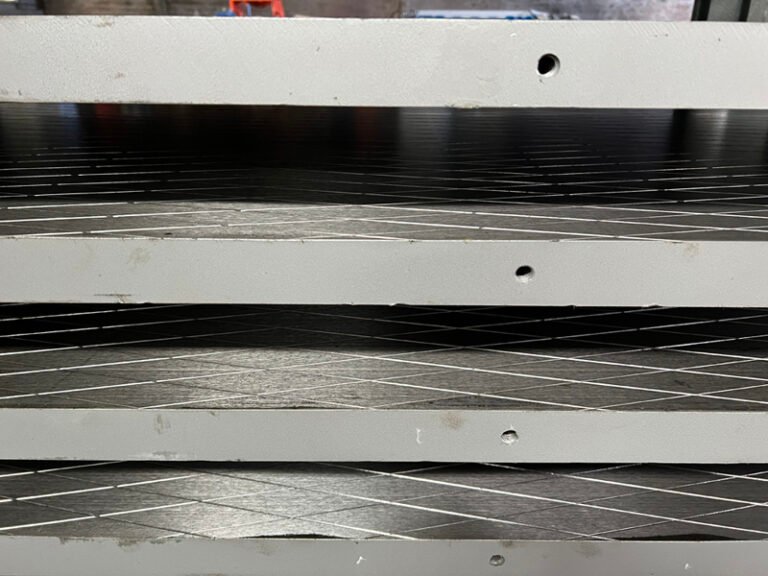

Indonesian hot press customizing the double inlet and double outlet heat cycle hot platens

An Indonesian client with a hot press veneer board dryer machine encountered inefficiency with the original design, which featured a single inlet and outlet for heat. Additionally, the heat plates lacked surface…

Customize peeling machine rollers for customer

At KING LINKWOOD MACHINERY CO., LTD., we understand the importance of high-quality spare parts in maintaining the efficiency and longevity of peeling machines. One of our key products is the peeling machine…