CONNECTING WOOD WITH PRECISION

100-160mm Thick Hot Press Plates | High-Performance Parts for Short Cycle Presses

PRODUCT PARAMETERS

- Material: Q235,Q345 steel plates.

- Thickness: 100-180 mm

- Heat Recycle: 4/6 inlet and 4/6 outlet or 6

- Customize and Design: size and heat recycle method, hole drill.etc

Description

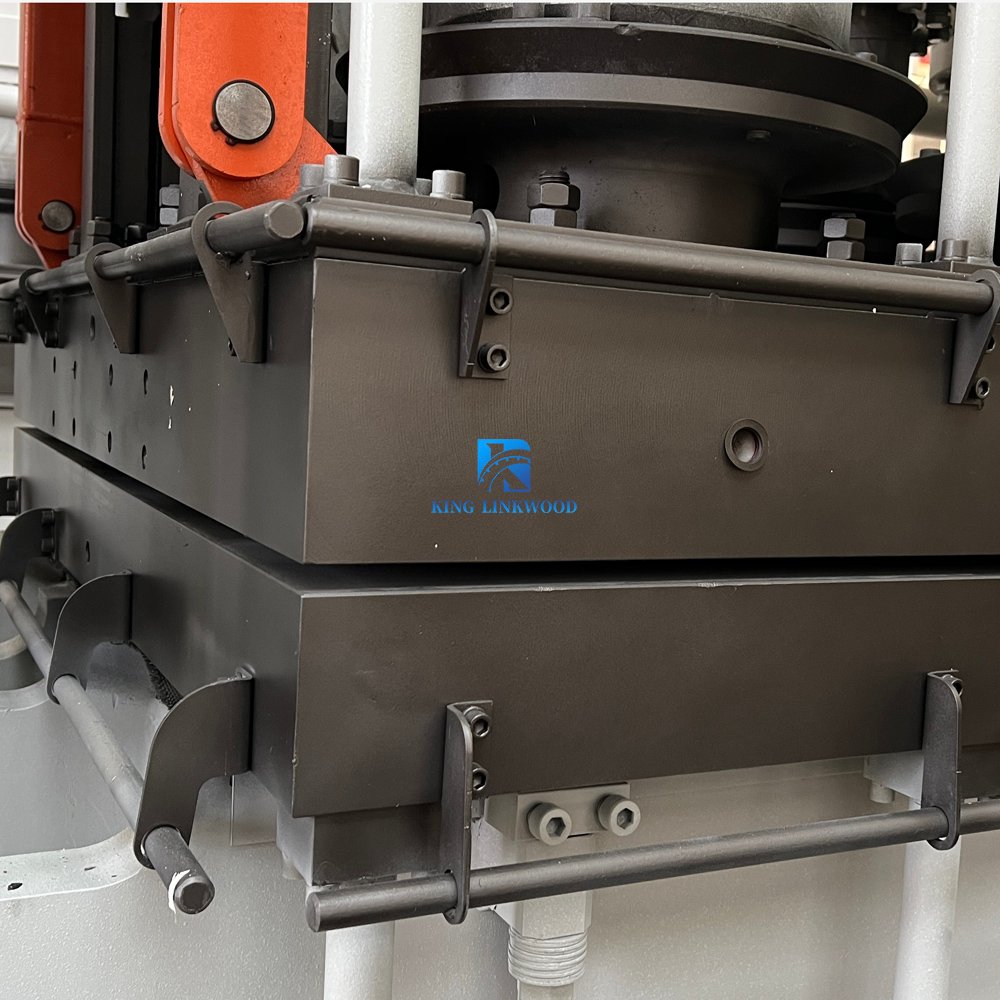

As a key core component for 900T–3200T short cycle laminating hot presses, our thick hot press plates are designed to boost efficiency, durability and precision in furniture board, flooring and decorative panel production.

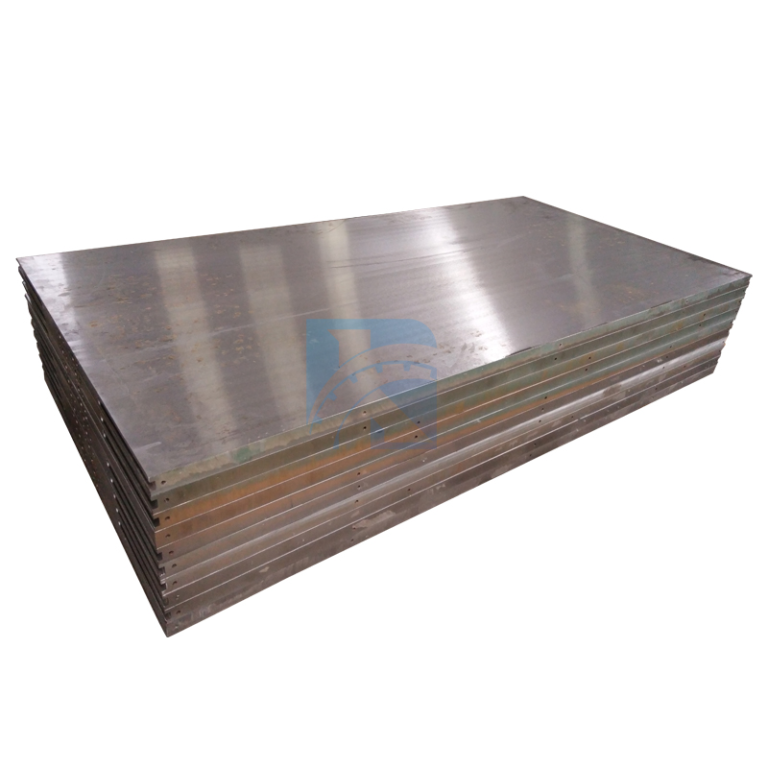

Available in standard thicknesses of 100mm, 120mm, 140mm, 160mm, plus custom sizes, these plates handle tough industrial conditions, delivering consistent laminating results that meet strict quality standards for furniture, construction and interior design industries.

PRODUCTS INTRODUCTIONS:

Built for heavy-duty double-sided laminating hot press operations, our thick hot press plates work with pressures from 9000KN to 28000KN. They ensure even heat and pressure across the entire surface, avoiding bubbles, warping and uneven adhesion—critical for perfect large-format boards (1220×2440mm, 1220×2750mm, 1830×2750mm, etc.).

Whether laminating particleboard, MDF, plywood or decorative films, these plates integrate smoothly with your production line to increase output and reduce waste.

PRODUCTS SPECIFICATION:

| Specification Category | Details |

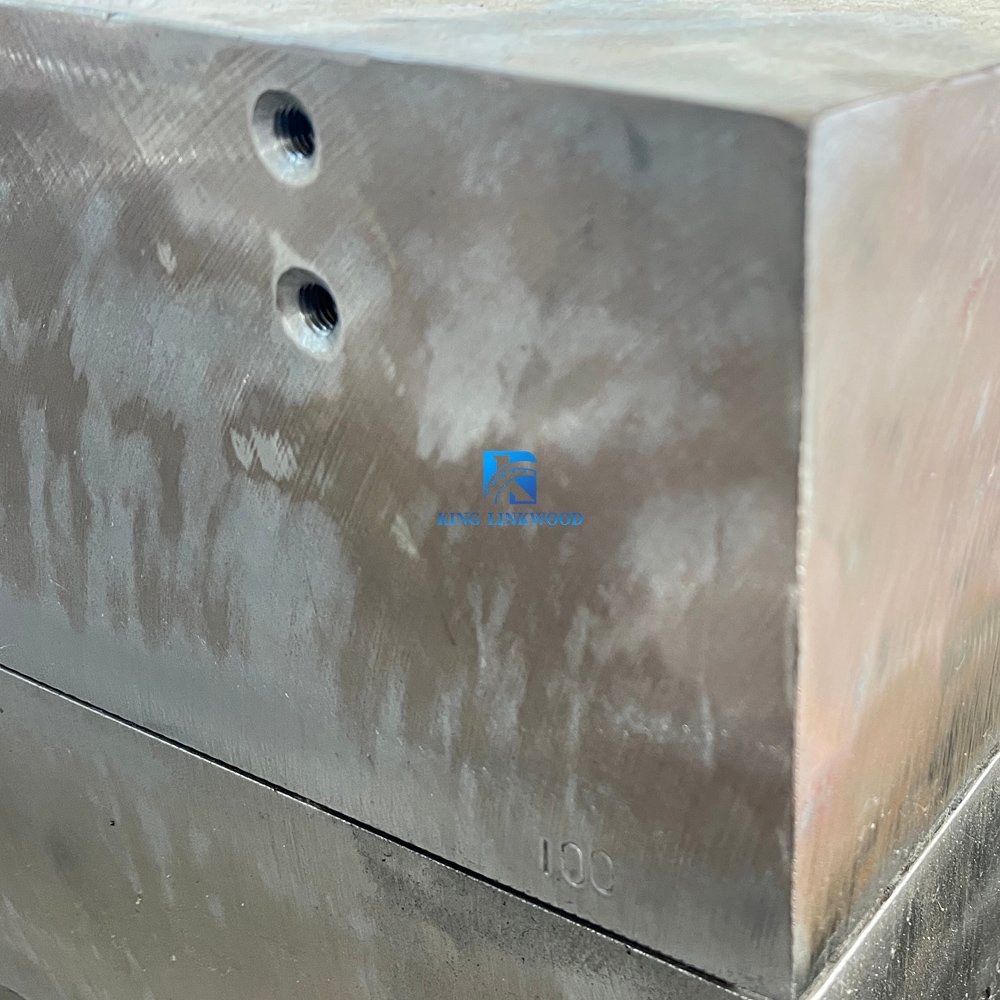

| Core Thickness Options | 100mm, 120mm, 140mm, 160mm; Custom thickness (up to 180mm) available on request |

| Compatible Hot Press Tonnage | 900T–3200T double-sided laminating hot presses (upper-mounted cylinder type included; |

| Max Pressure Resistance | 9000KN–28000KN |

| Suitable Board Sizes | 1220×2440mm, 1220×2750mm, 1830×2750mm, 2150×2750mm; 48ft, 49ft, 58ft, 68ft, 69ft, 78ft, 79ft (max plate size: 6x12ft) |

| Material Feature | Q235B/Q345/Q355; High-grade heat-conductive material; Corrosion & fatigue-resistant surface treatment electrophoretic coating) |

| Oil Heating Recycle Design | 4 in 4 out, 6 in 6 out. Customize design. |

| Machining Process | Precision CNC machining; |

| Thermal Performance | Continuous working temperature: 180–250℃]; Even heat distribution, no hot spots |

| Key Application | Furniture boards, laminate flooring, cabinet panels, door panels, decorative architectural laminates |

| Customization Service | Tailor-made thickness, surface treatment & size; Free technical consultation;drilled holes/grooves customization |

KEY ADVANTAGES:

Reinforced Thick Structure for Stable Performance

Standard thicknesses (100/120/140/160mm) and custom options are engineered to handle 9000KN–28000KN pressure. They minimize deformation during long-term high-pressure work, maintaining flatness for consistent laminating quality—ideal for large-format board processing.

Efficient Heat Conduction & High-Temp Resistance

Made from high-quality heat-conductive materials with strong thermal stability, these plates withstand continuous high temperatures needed for short cycle laminating. They heat decorative films, veneers and coatings quickly and evenly, ensuring vivid patterns and strong, long-lasting adhesion without hot spots.

Precision Machining for Long Service Life

Produced to the same strict standards as our hot press frames, the plates undergo CNC machining for an ultra-smooth surface. This reduces friction with workpieces, prevents sticking, and lowers maintenance needs. The corrosion and fatigue-resistant surface treatment ensures durability under frequent heavy-load use.

Wide Compatibility with Hot Press Models

Custom-designed to fit all 900T-3200T double-sided laminating hot presses, including upper-mounted cylinder types. They work with various board sizes (48ft to 79ft) and install easily without modifying existing equipment, supporting versatile production needs.

Energy-Saving Design for Cost Efficiency

Optimized heat retention reduces energy loss during operation. When paired with our high-pressure heat-insulating polymer plates (replacing traditional epoxy resin boards), they cut power consumption by up to 15% and extend hydraulic cylinder life—saving on long-term energy and maintenance costs.

Application Scenarios

Our thick hot press plates are ideal for short cycle laminating production lines focused on:

Furniture Boards: Particleboard, MDF, plywood laminated with decorative films or veneers

Flooring Products: Laminate flooring, engineered wood flooring, vinyl composite flooring

Cabinet & Kitchen Panels: High-gloss, matte or wood-grain laminated cabinet doors and countertops

Door Panels: Solid wood composite doors, fire-resistant doors, decorative interior doors

Other Decorative Panels: Wall panels, ceiling panels, customized architectural laminates

Why Choose Our Thick Hot Press Plates?

Reliable Compatibility: Tailored for 900T–3200T double-sided hot presses, ensuring perfect fit and performance.

Higher Productivity: Even heat and pressure cut processing time by 10–20% and reduce waste significantly.

Durable Quality: Thick structure and precision machining extend service life by 30% compared to standard plates, resisting wear, corrosion and high temperatures.

Cost Savings: Lower energy use, less maintenance and reduced downtime maximize your return on investment.

Professional Expertise: Backed by 10+ years of hot press R&D experience, with custom solutions for unique needs.

Customization & Service

Custom Thickness: We offer tailor-made thicknesses beyond 160mm to match your press model and production requirements.

Technical Support: Our engineering team provides free installation guidance and on-site debugging for bulk orders.

Quality Guarantee: All products pass strict pressure and heat conduction tests before delivery, with after sale service warranty.

Contact Us

Ready to change or upgrade your short cycle laminating line with high-performance thick hot press plates? Fill out the form below or directly call us or email our sales team for a free quote and technical consultation.

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888