CONNECTING WOOD WITH PRECISION

Material Selection Guide for Woodworking Rollers: 40Cr Steel vs. 45# Steel

Choosing the correct material for woodworking rollers directly impacts machine performance, service life, and product quality.

Among the most commonly used materials are ’40Cr steel’ and ‘45# steel’, each suited to different applications.

Material Comparison

|

Material |

Key Features |

Typical Applications |

|

40Cr Steel |

High wear resistance, high precision, excellent toughness |

Diamond rollers for particleboard/MDF spreaders, precision veneer lathe rollers |

|

45# Steel |

Good elasticity, cost-effective, easy processing |

Friction rollers, log debarker rollers, gear-type rollers |

Application-Based Recommendations

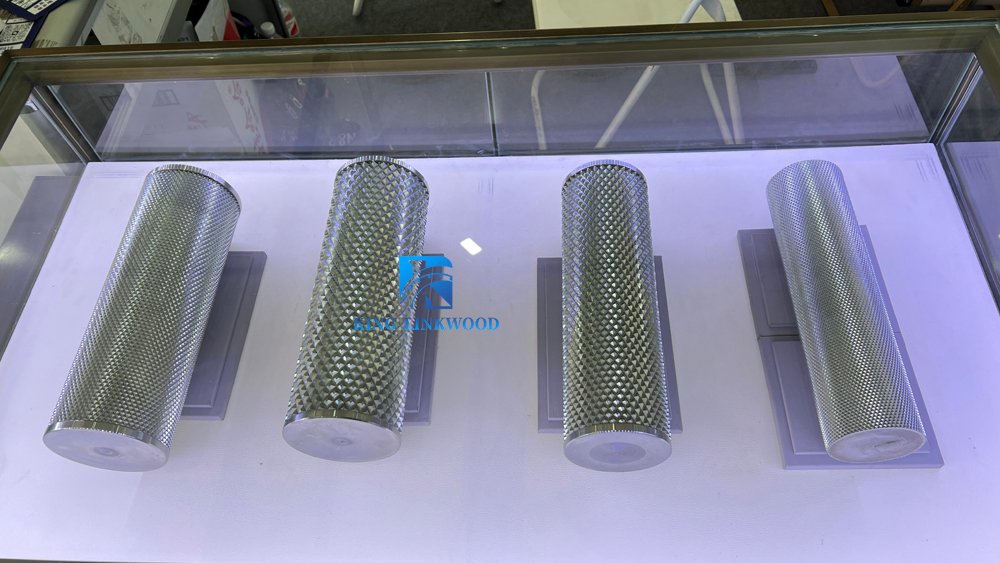

Diamond rollers for spreader machines,paving machines:

40Cr steel is preferred due to its wear resistance and precision stability.

Friction and debarker rollers:

45# steel offers sufficient strength and elasticity at a lower cost.Material selection should be based on roller function, load conditions, and precision requirements.

Our engineering team provides ‘application-based recommendations’ to ensure optimal performance and cost efficiency.