CONNECTING WOOD WITH PRECISION

6 Key Signs Your Diamond Roller Needs Replacement

Introduction

In particleboard and MDF forming lines, the **diamond roller** plays a decisive role in material distribution, density uniformity, and board surface quality.Over time, even high-quality rollers experience wear. Identifying replacement timing early helps avoid unstable production and unplanned downtime.

Below are ‘six practical signs’ indicating your diamond roller may need replacement.

Surface Wear or Pattern Damage

Visible scratches, pits, or uneven wear reduce material distribution accuracy.

If the diamond pattern becomes blurred or flattened, paving performance will decline.

Diameter or Runout Deviation

Regular measurement is recommended.

When runout exceeds industry-accepted tolerance (±0.05 mm/m), feeding stability and mat uniformity are affected.

Abnormal Vibration or Noise

Increased vibration or noise during operation may indicate:

* Bearing wear

* Shaft deformation

* Internal imbalance

Unstable Board Quality

Frequent density variation or rough board surfaces—despite correct machine adjustment—often point to roller wear.

Reduced Production Efficiency

A noticeable drop in output without other mechanical causes often correlates with severe roller wear.

Service Life Reached

Even without visible damage, most **high-quality diamond rollers** have a typical service life of **3–5 years** under normal operation.

Conclusion:Timely replacement of diamond rollers ensures stable board quality and prevents costly downtime.

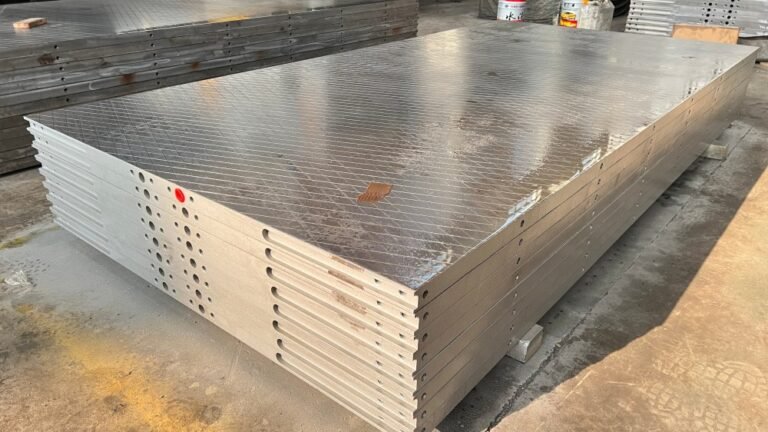

We manufacture **high-precision 40Cr steel diamond rollers** with customized patterns for particleboard and MDF forming machines.

—