CONNECTING WOOD WITH PRECISION

Two Essential Rubber Rollers for Woodworking Machinery

NBR Rubber Roller for Glue Spreading Machine

As a core component in woodworking machinery, our high-performance Nitrile Butadiene Rubber (NBR) roller is engineered specifically for glue spreading machines, putty machines, and veneer splicing machines—excelling in both gluing and conveying applications.

Produced with premium NBR materials, it delivers exceptional oil resistance, wear resistance, and strong adhesion, ensuring uniform glue application and stable material transmission during wood processing.

The roller core is precision-manufactured from 45# seamless steel pipe or alloy steel, undergoing heat treatment, machining, and hard chrome plating to enhance structural durability and corrosion resistance. Strict quality control over vulcanization and surface finishing guarantees consistent hardness (Shore A 60-80, customize) and a smooth surface that prevents glue leakage and material damage. This NBR rubber roller ensures extended service life, reduced maintenance costs, and improved production efficiency, making it ideal for furniture manufacturing, cabinet production, and veneer processing plants.

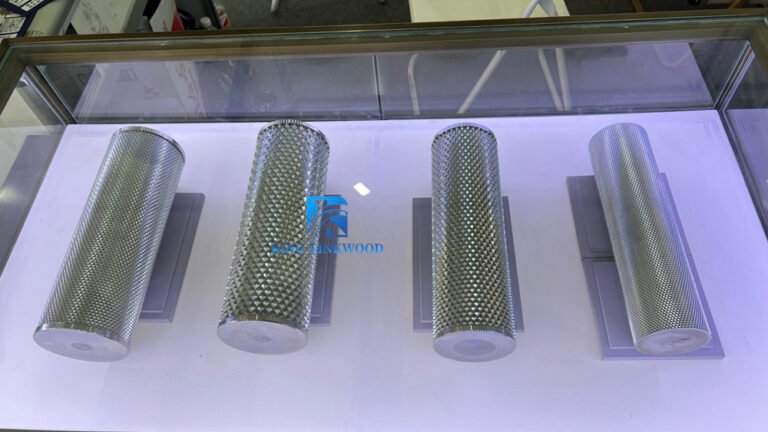

Polyurethane (PU) Veneer Clipper Roller

Designed exclusively for veneer clipper machines and veneer peeling machines, our Polyurethane (PU) rubber roller meets the rigorous demands of wood processing with exceptional elasticity and impact resistance.

Made from high-quality PU material, it offers superior tear resistance, abrasion resistance, and strong grip—ensuring precise, smooth feeding of veneers during cutting and peeling operations. The metal core (45# seamless steel pipe or alloy steel) features advanced sandblasting and adhesion treatment, guaranteeing firm bonding between the PU layer and core to prevent delamination even under high-speed rotation.

A precisely ground surface and adjustable hardness (Shore A 70-90) minimize veneer waste by maintaining stable material positioning, while chemical resistance ensures compatibility with various wood treatments. Suitable for plywood factories, veneer mills, and woodworking workshops, this roller delivers reliable performance and enhanced operational efficiency.

For these 2 kinds rubber roller for woodworking. We can customize for you. With different diameter rollers, length and rubber layers thickness.etc to well meet with your glue spreader or veneer peeling machine needs. Choose a reliable rubber roller spare parts, save your costs and make your machine stay in a high efficient working situation. Feel free to contact kinglinkwood woodmachine parts.