CONNECTING WOOD WITH PRECISION

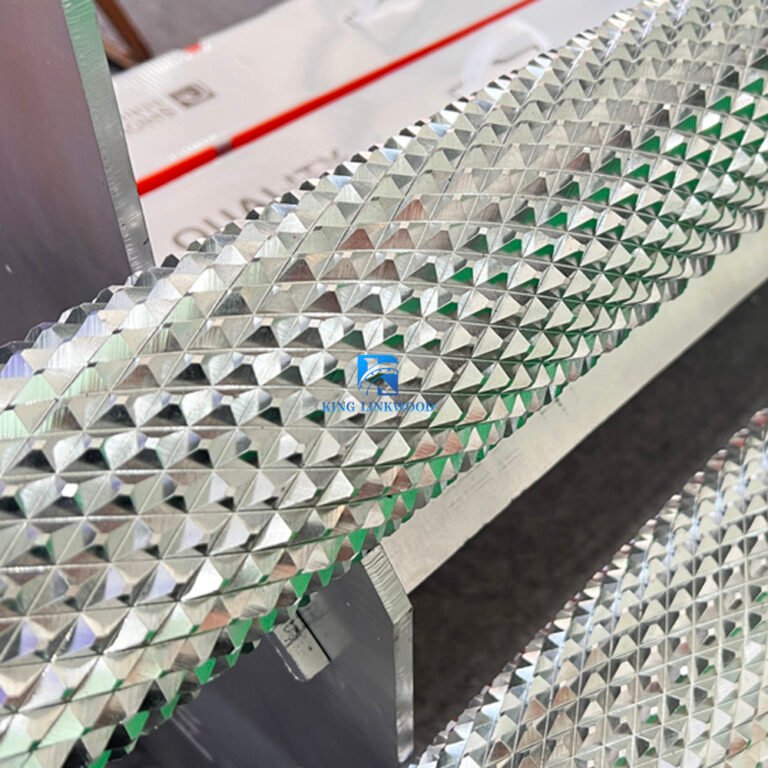

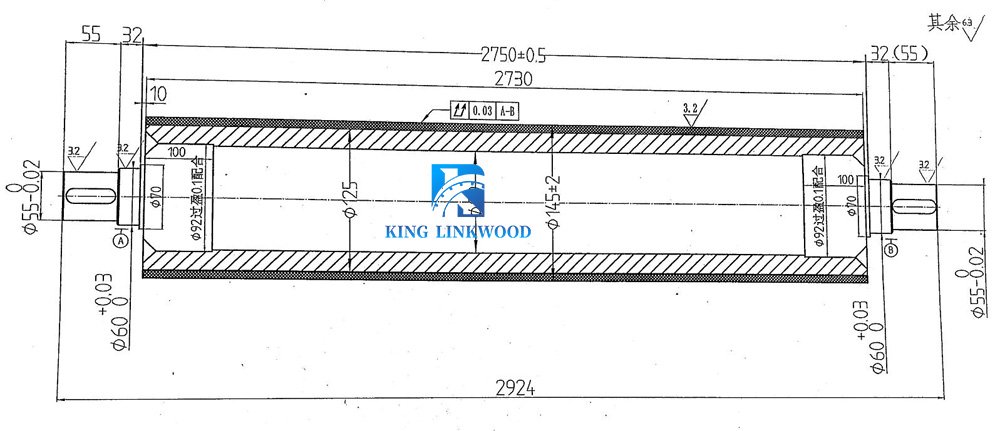

Veneer Clipper Roller, Polyurethane Rubber Roller

PRODUCT PARAMETERS

- Rubber Material: Polyurethane (PU)

- Roller Material: Thick Wall Seamless Steel Pipe.

- Seamless Steel Pipe Wall Thickness: 10mm.

- Rubber Thickness: 10-15mm.

- Diameter/size: Customize.

Description

Core Advantages

- High-quality Polyurethane (PU) material: Elastic, impact-resistant, tear-proof, strong grip

- Stable metal core (45# seamless steel/alloy steel): Sandblasted + adhesion-treated to avoid delamination

- Precision-ground surface & hardnesscustomize : Reduces veneer waste

Applications

Veneer clipper machines, veneer peeling machines,veneer cutting machine.etc — for precise feeding and improve veneer cuting performance.

Ideal For

Plywood factories, veneer mills, woodworking workshops. Support customizing. No matter special size or old type peeling machines, veneer clipper machines,both can design and customize for you.

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888