CONNECTING WOOD WITH PRECISION

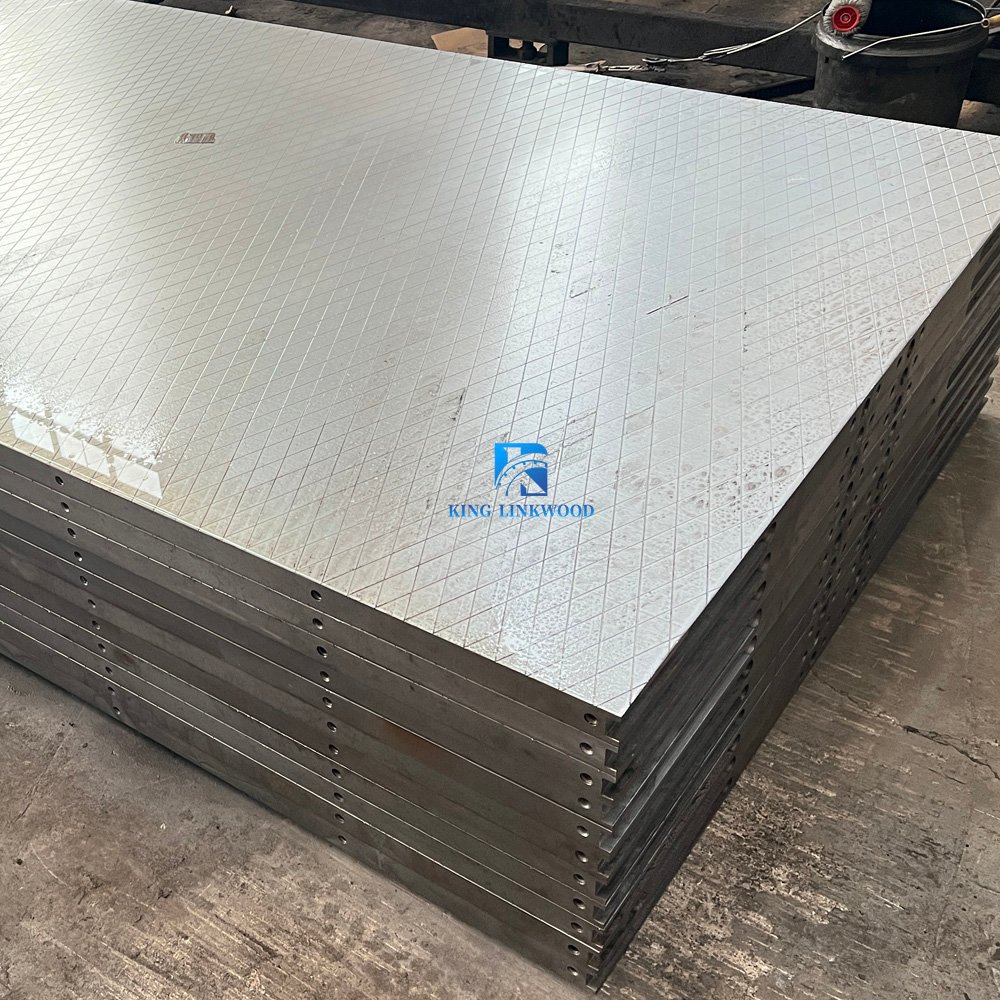

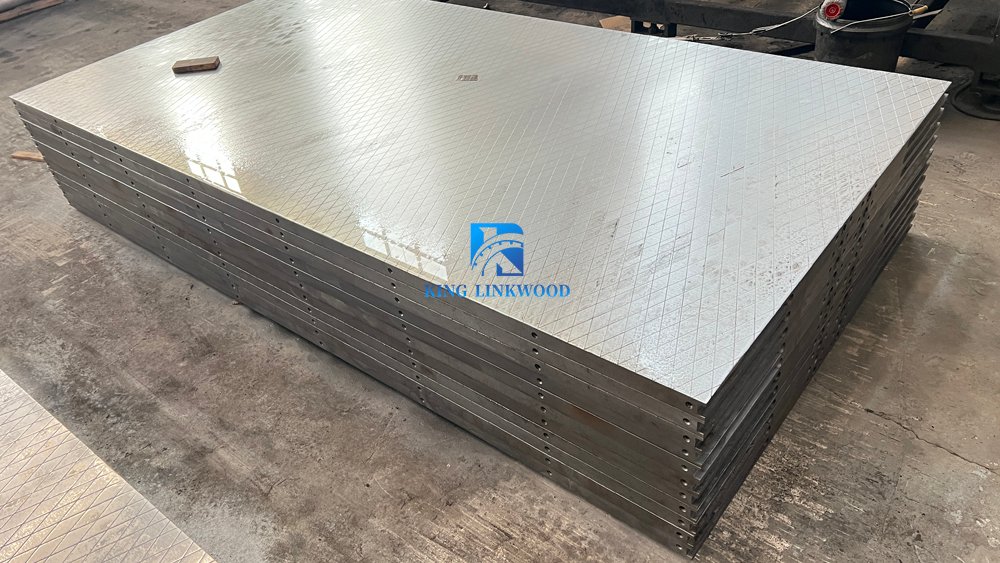

Quality Surface Grooved Hot Platen for Plywood Production Machinery

PRODUCT PARAMETERS

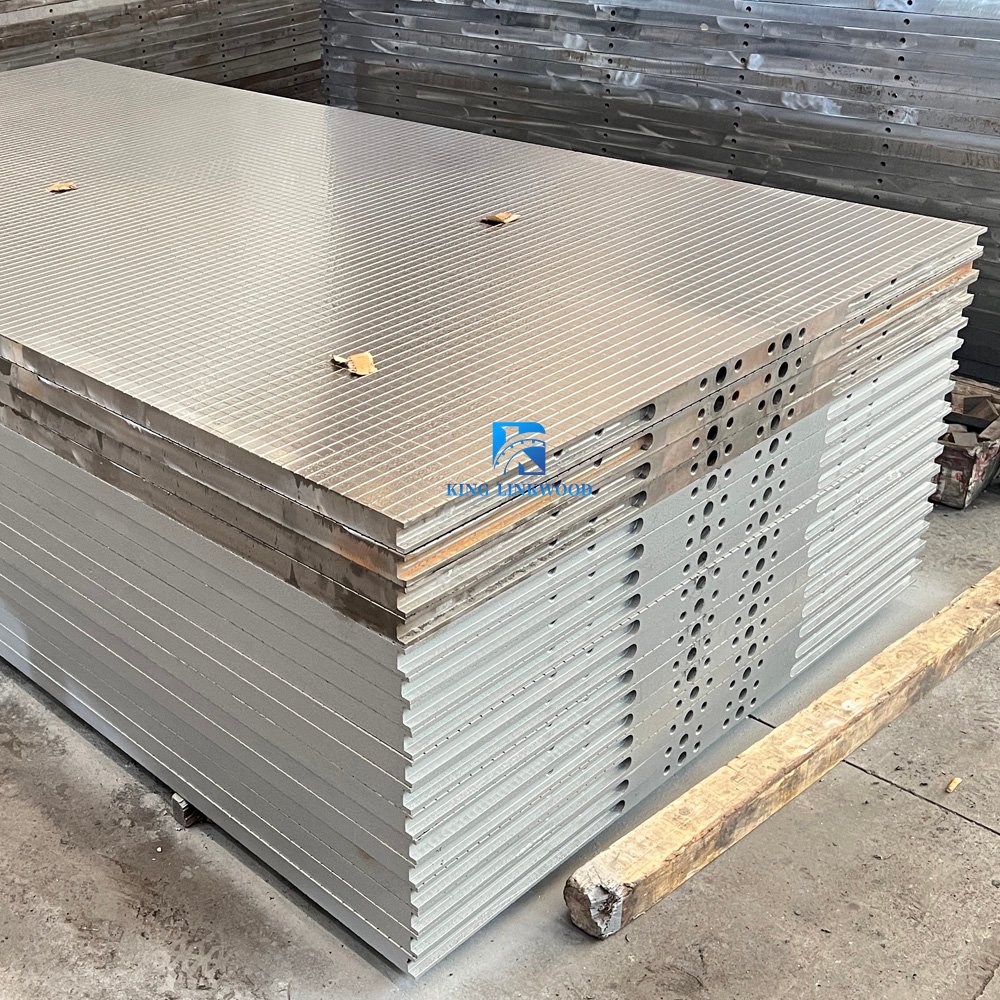

- Material: Q235,Q345 steel plates.

- Thickness: 45,52mm~100mm

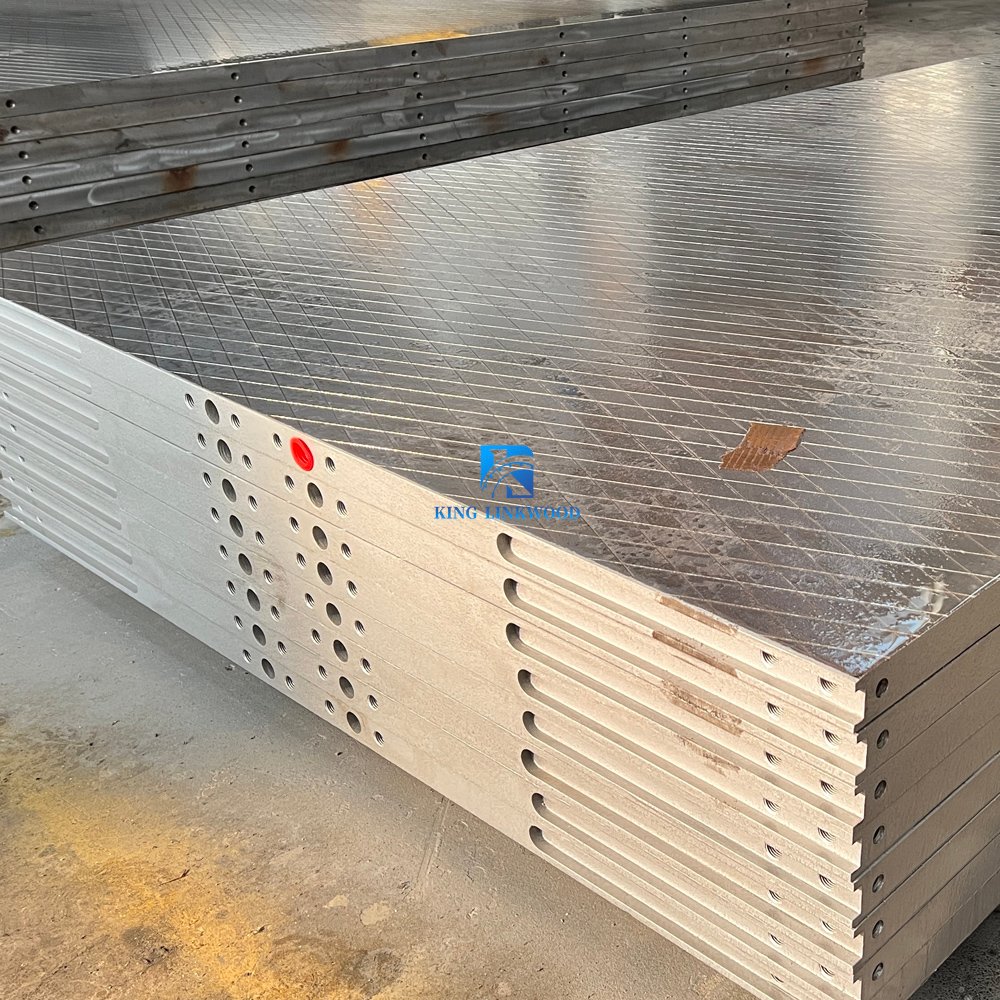

- Groove: saqure type grooves, cross-hatched grooves.etc

- Heat Recycle: double in double out.

- Customize and Design: hot plate size and surface grooves types.

Description

Quality Surface Grooved Hot Platen for Plywood Production Machinery

PRODUCTS INTRODUCTION:

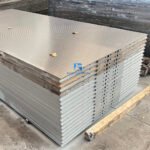

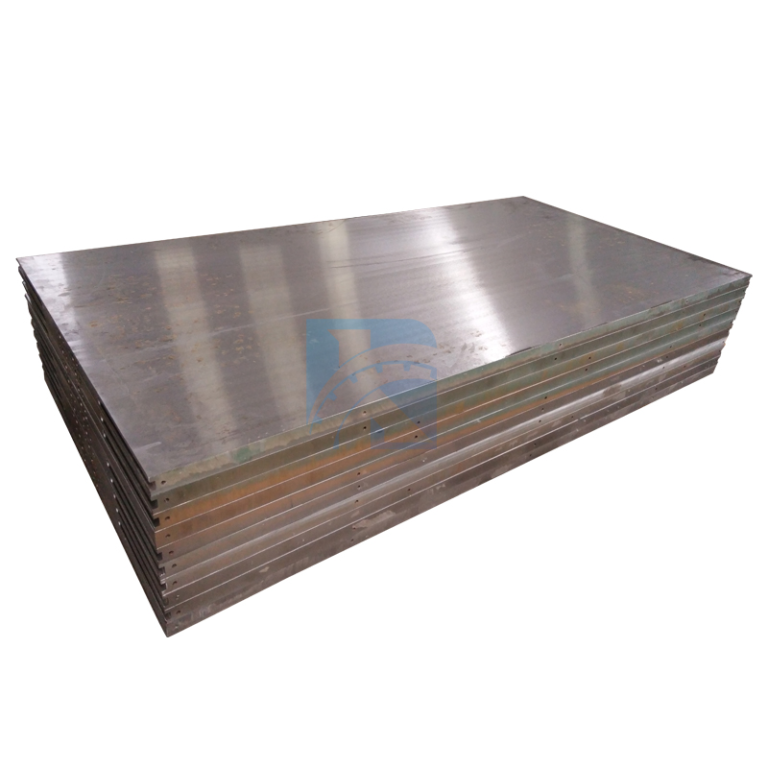

The quality surface grooved hot platen is a high-precision, application-specific component developed exclusively for plywood production machinery. Its defining feature is the precision-machined grooves on the working surface.This platen is widely used in core plywood lamination, face veneer lamination, and multi-layer plywood pressing processes, directly contributing to the production of high-quality, high-strength plywood products.

KEY ADVANTAGES:

Precision Groove Structure for Adhesive & Heat Management: The surface grooves are designed with a uniform spacing and a precise cross-sectional shape (typically U-shaped or V-shaped, with a width of 2mm–5mm and depth of 0.5mm–1mm). These grooves serve two critical functions:

- Adhesive Overflow Channel: During plywood pressing, excess adhesive (which can cause surface “glue spots” if left on the plywood surface) flows into the grooves, keeping the plywood surface clean and reducing post-processing (e.g., sanding) workload.

- Heat Dissipation & Uniformity Enhancement: The grooves create micro-channels for heat circulation, preventing localized heat accumulation on the platen surface. This further improves the surface temperature uniformity (tolerance ≤2.5°C, better than the industry average of 3°C–5°C) and ensures that the adhesive in the plywood’s internal layers is fully cured.

High-Strength Surface for Wear Resistance: The grooved surface undergoes a precision grinding and hardening treatment (surface hardness ≥HRC 45), making it highly resistant to wear from repeated contact with plywood blanks and adhesive residues. This ensures that the groove dimensions remain stable over long-term use (service life ≥5 years under normal operating conditions), avoiding the need for frequent platen replacement.

Technical Specifications

Material: Q235/Q345 steel (withstands 1.2–2.0MPa pressure & 120–180°C temperature). Reinforced Q345. alloy steel option for ultra-thick plywood (≥20mm) to boost load-bearing capacity.

Groove Precision: Groove spacing tolerance ≤0.1mm, width/depth tolerance ≤0.05mm; groove interior smoothness ≤1.5μm (easy to clean).

Heat Carrier & Channels: Compatible with oil/steam. Internal cross channels: 30mm (≥1500×2600mm large platens) or 25mm (medium platens), 90mm channel spacing.

Size & Installation: Standard sizes ; custom options available. Mounting hole position tolerance ≤0.1mm for seamless press alignment.

Application Value for Manufacturers

Quality Upgrade: 90% reduction in surface defects (glue spots, uneven color); bonding strength meets standard.

Efficiency Boost: 30% less post-pressing sanding time; 10–15% shorter pressing cycles, increasing production capacity.

Cost Savings: 50% lower platen replacement frequency vs. conventional models; easy-to-clean grooves cut maintenance labor & adhesive waste.

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888