CONNECTING WOOD WITH PRECISION

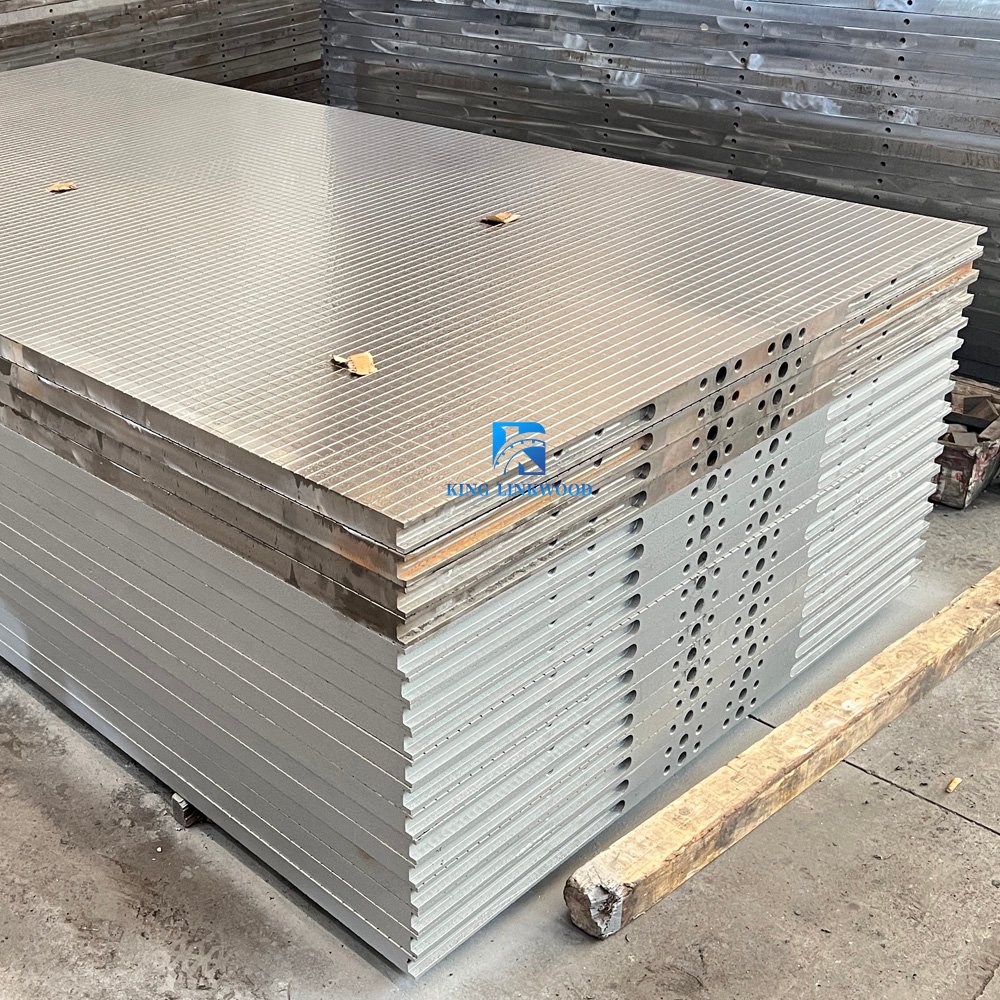

Square Pattern Groove Hot Platen for Veneer Dryer Machine and Plywood Working

PRODUCT PARAMETERS

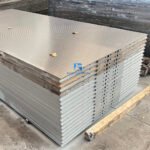

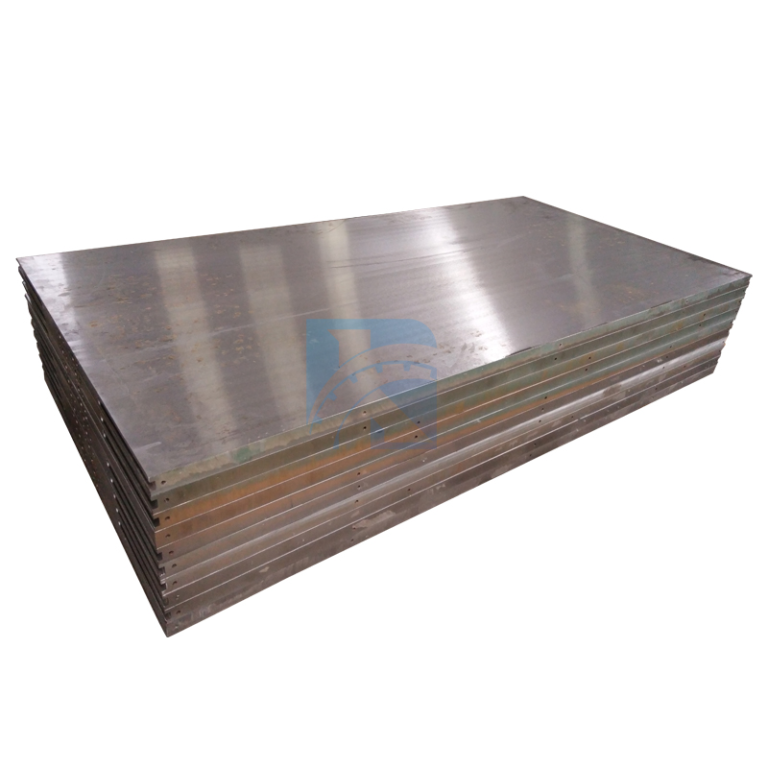

- Material: Q235,Q345 steel plates.

- Thickness: 45,52mm~100mm

- Groove: saqure type grroves, cross-hatched grooves.etc

- Heat Recycle: double in double out.

- Customize and Design: hot plate size and surface grooves types.

Description

PRODUCTS INTRODUCTION:

The square grooved pattern hot platen is a specialized heat transfer component engineered for two core applications: veneer dryer machines and plywood production,Particle board,MDF board and other mould products production processes. Unlike flat-surface hot platens, its unique square-patterned grooved surface structure is designed to optimize heat exchange and moisture discharge efficiency.

KEY ADVANTAGES:

Enhanced Heat Transfer for Veneer Drying: In veneer dryer machines, the square pattern on the platen surface like moisture running path, increases the veneer plywood moisture out let speed. And this not only accelerates the evaporation of moisture from the veneer but also ensures that heat is transferred uniformly across the veneer’s entire surface—preventing localized over-drying (which causes brittleness) or under-drying (which leads to mold growth during storage).

Optimized Pressure Distribution for Plywood Working:

Minimizes the occurrence of “bubble defects” (caused by uneven adhesive curing) and ensures that each layer of veneer in the plywood is firmly bonded, enhancing the overall structural strength of the plywood.

Technical Specifications Aligned with Application Needs

Material: Available in Q235B (for standard plywood production lines) and Q345 (for heavy-duty veneer dryer machines or high-thickness plywood production) to ensure resistance to high-temperature deformation and long-term mechanical stability.

Square Pattern Surface Groove: square pattern grooved surface customization .veneer (e.g.0.5mm–3mm) and the requirements of the plywood lamination process. The depth of the pattern is strictly controlled to avoid damaging the veneer surface while maintaining optimal heat transfer efficiency.

Heat Carrier & Temperature Control: The surface temperature uniformity tolerance is ≤3°C, ensuring consistent moisture removal; for plywood lamination, the temperature can be precisely adjusted between 80°C–180°C to match different types of wood adhesives (e.g., urea-formaldehyde resin, phenol-formaldehyde resin).

Size & Customization: Standard sizes to common veneer dryer machines (e.g., 1370×2700mm for 4×8ft veneers) and plywood press machines. Custom sizes are available based on the equipment’s working width and length. Thickness options range from 12mm to 100mm, with thickness tolerance ±1mm to ensure seamless installation with the machine’s pressing system.

Durability & Maintenance: The square pattern surface undergoes a special anti-corrosion treatment (e.g., electroplating or high-temperature paint coating) to resist corrosion from moisture (during veneer drying) and adhesive residues, extending the platen’s service life. The internal channels are designed with easy-to-clean interfaces, reducing maintenance time and costs.

Application Benefits

For veneer dryer machines: Reduces veneer drying time by 15%–20% compared to flat-surface platens, improves veneer drying uniformity (qualification rate ≥95%), and maintains the veneer’s natural texture and flexibility.

For plywood working: Enhances plywood bonding strength by 10%–15%, reduces the rejection rate due to bonding defects to ≤1%, and adapts to various wood species (e.g., pine, oak, birch) and plywood thicknesses (3mm–28mm).

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888