CONNECTING WOOD WITH PRECISION

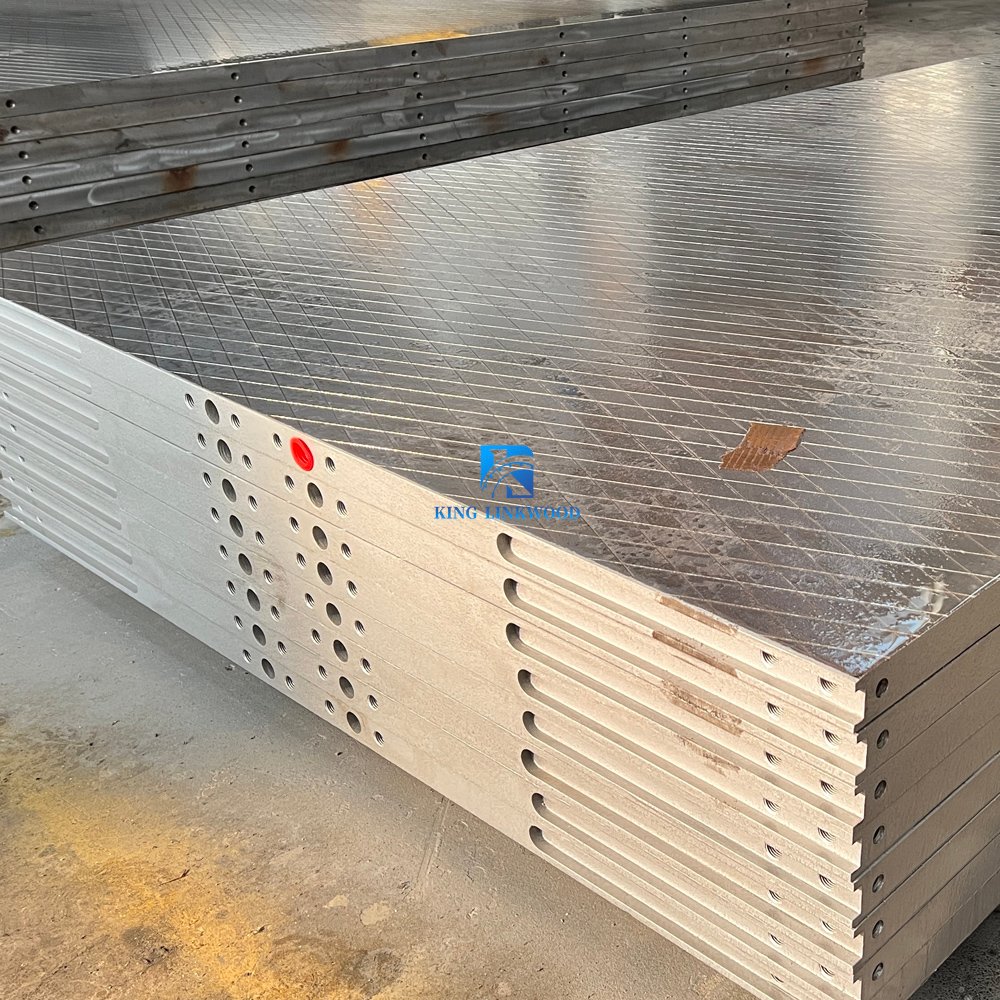

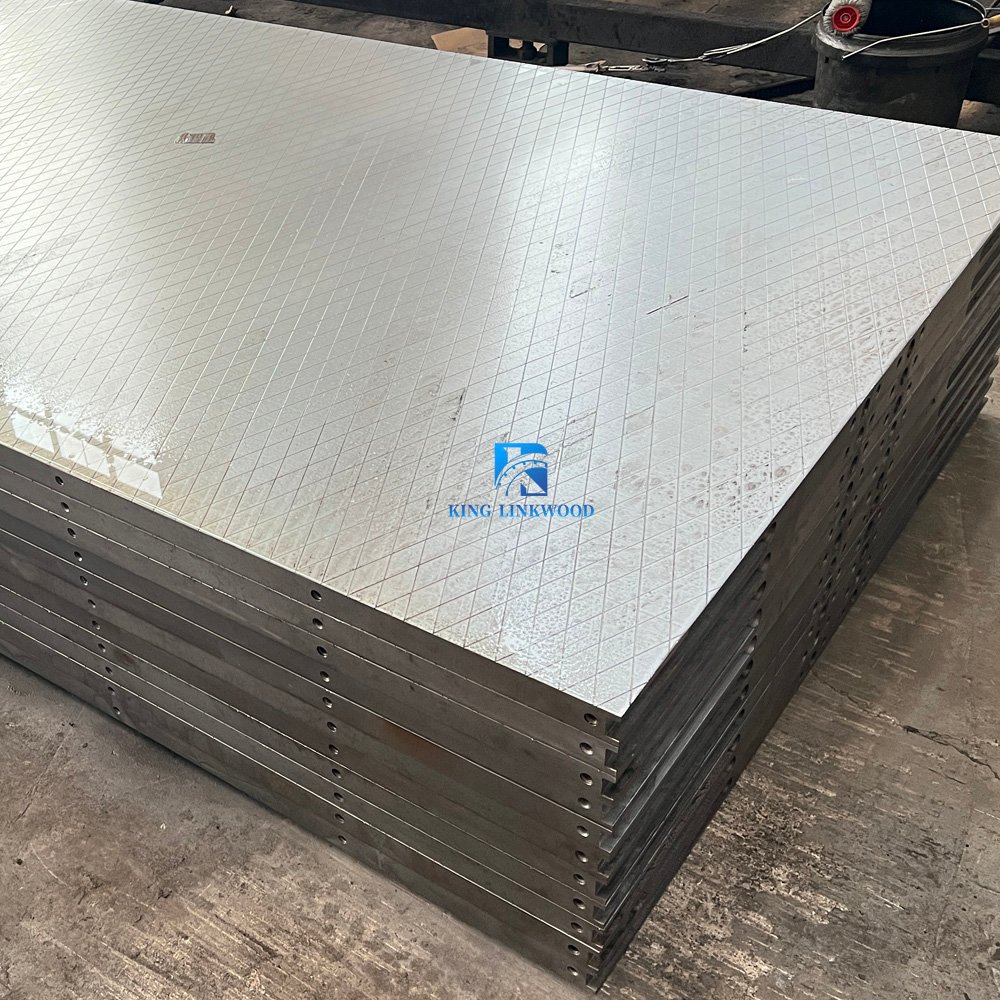

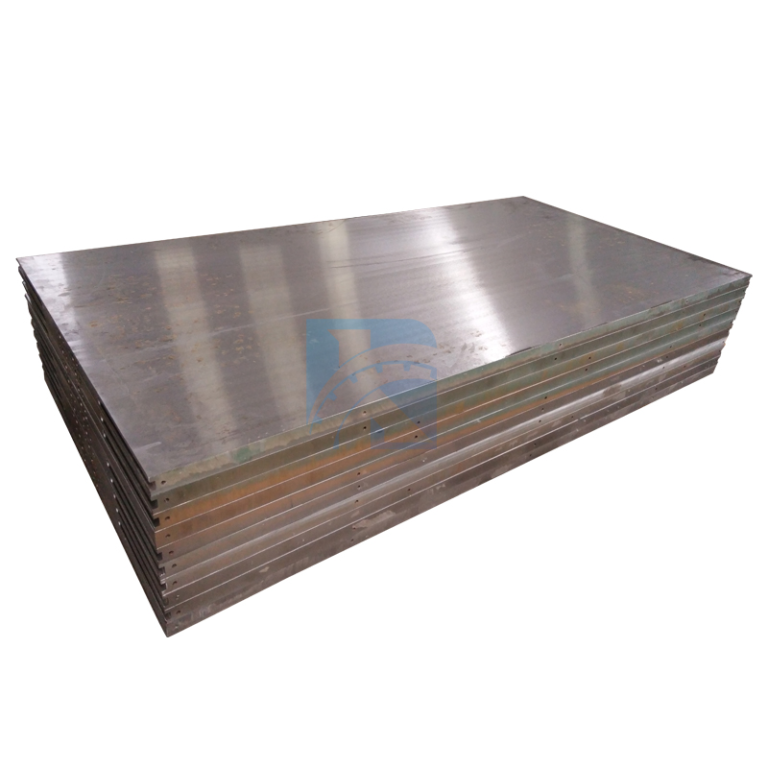

Hot Press Platen with Cross-Hatched Grooves, Diamond-Grooved Hot Press Plate

PRODUCT PARAMETERS

- Material: Q235,Q345 steel plates.

- Thickness: 45,52mm

- Groove: cross-hatched grooves. (customized)

- Heat Recycle: double in double out.

Description

PRODUCTS OVERVIEW:

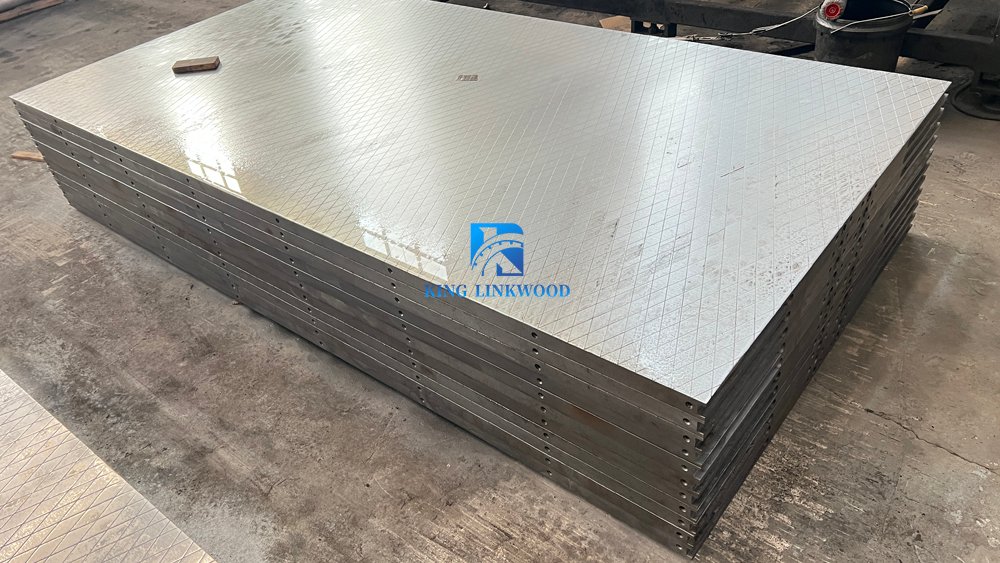

With an advanced designing diamond-patterned grooved surface, specifically made to improve veneer drying quality and enhance drying efficiency- the ideal choice for high-demand hot press applications.

KEY FEATURES & BENEFITS.

Diamond-Grooved Surface Design

The precision-machined cross-hatched grooves create a highly efficient pathway for moisture to escape from veneer during the hot pressing process. This reduces 20% drying time compared to smooth platens, ensuring uniform moisture removal and minimizing the veneer warping or defects.

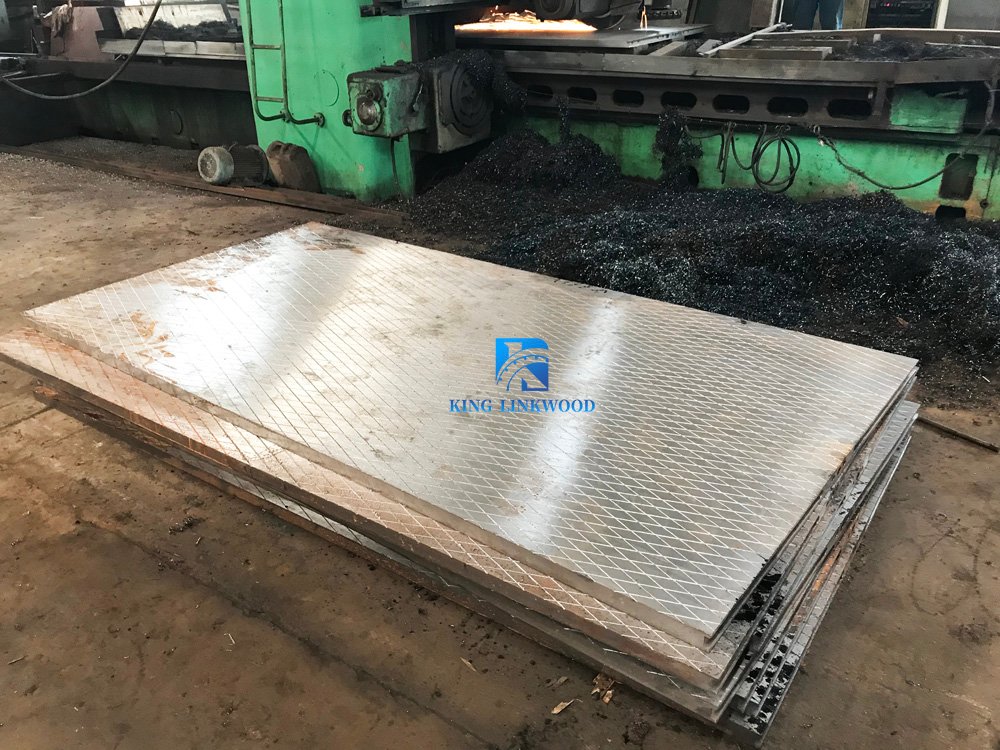

High-Quality Material Construction.

Manufactured from standard Q235 and Q345 structural steel, resistance to deformation under high-temperature and high-pressure conditions. Working well in continuous production environments.

Customization Solutions.Provide groove/size customize to meet your specific production requirements:Custom Dimensions: Groove Pattern Customization: Surface Finishing Options: Additional treatments such as polishing or anti-corrosion coating are available upon request.

Industry Applications

This diamond-grooved hot press platen is widely used in:

Veneer Dryers: Optimizes moisture extraction for fast, uniform drying of natural wood veneers.

Plywood Hot Presses: Ensures efficient heat transfer and moisture removal during the plywood lamination process, resulting in stronger bonds and higher-quality panels.

Laminated Board Production: Suitable for both softwood and hardwood veneer processing, as well as engineered wood panel manufacturing.

SPECIFICATION:

|

Parameter |

Details |

|

Material Grade |

Q235, Q345 (other high-strength steel grades available on request) |

|

Groove Pattern |

Standard diamond/cross-hatched (custom patterns available) |

|

Thickness Range |

20mm–150mm (customizable) |

|

Surface Tolerance |

±0.1mm for groove depth and spacing |

|

Temperature Resistance |

Up to 250°C (continuous operation) |

USAGE SCENARIO:

✅ Why Choose Our Diamond-Grooved Hot Press Platens?We combine precision machining, high-grade materials, and customizable design to deliver a platen that can improve product quality, and lowering long-term maintenance costs. No matter you are veneer wood process factory or hot press machine manufacturing workshops, feel free to call us.

FAQs

Yes, we offer fully customization feeding screws. Share your machine model, required dimensions, and thread specifications, and we’ ll manufacture the suitable screws part tailored to your needs.

Our feeding screws are compatible with most standard spindle-less veneer peeling machines in the market made by China. If you have a unique machine setup, we can design a compatible screw for you.

We use high-quality alloy steel, known for its durability, strength, and resistance to wear, ensuring long-lasting performance.

You can provide details such as the machine model, MFG data and current screw diameter ,length and screw thread specifications. Our team will assist in identifying or designing the perfect fit.

Standard sizes are typically in stock for quick delivery. Customized screws may require 5-7 work days production time, depending on the complexity and quantity of the order.

Yes, we ship feeding screws worldwide with secure packaging to ensure they arrive in perfect condition.

Regular cleaning the strange, proper butter lubrication, and timely inspections can significantly extend the lifespan of the feeding screw. Avoid overloading the machine and log blocking to prevent undue stress.

Contact us via our website, email, or phone with details about your machine and requirements. Our team will assist you in placing an order and provide any necessary technical support.

REQUEST A QUOTE

RELATED PRODUCTS

-

微信: +8613866668888