CONNECTING WOOD WITH PRECISION

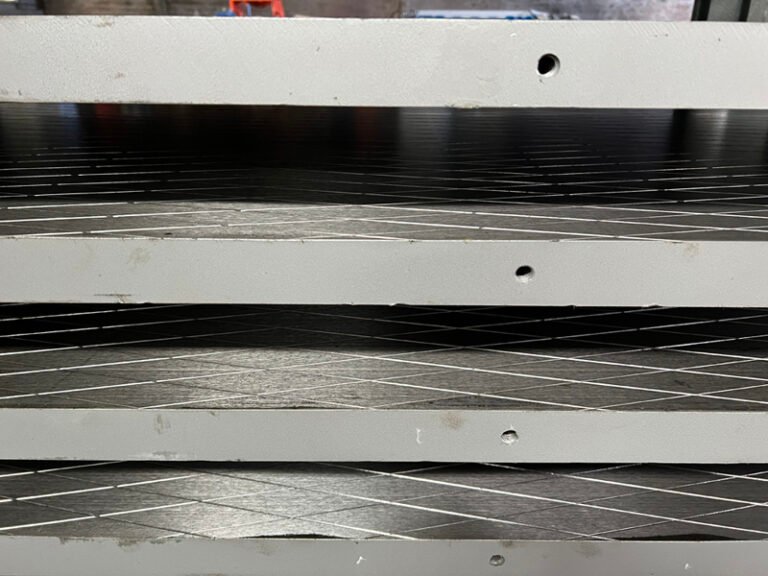

Customize peeling machine rollers for customer

At KING LINKWOOD MACHINERY CO., LTD., we understand the importance of high-quality spare parts in maintaining the efficiency and longevity of peeling machines. One of our key products is the peeling machine rotate roller spare parts, which are essential for the smooth operation of veneer peeling machines during the log holding and rotary cutting process.

Customer:

A plywood manufacturer in Southeast Asia faced frequent downtime and reduced production efficiency due to worn-out rollers in their peeling machine.

Challenge:

The customer was using outdated and poorly manufactured roller components, resulting in uneven veneer thickness, poor surface quality, and frequent machine breakdowns.

Solution:

We provided custom-designed peeling machine roller spare parts, engineered with high-quality materials for enhanced durability and performance. Our rollers feature:

- Precise machiningfor smooth operation and minimal friction.

- Durable materialsto withstand the heavy stress of the peeling process.

- Custom-fit designsto ensure seamless compatibility with the existing machinery.

Results:

After replacing the old rollers with our high-quality spare parts, the customer experienced:

- Improved veneer qualitywith consistent thickness and smoother surfaces.

- Reduced machine downtime, leading to higher production efficiency.

- Longer service lifeof the machinery due to the superior durability of our roller parts.

LINYI KING LINKWOOD MACHINERY CO., LTD. continues to support customers worldwide with reliable, precision-engineered parts that ensure the smooth operation of their woodworking machinery. If you’re facing similar challenges, contact us today to find the right solution for your production needs.